Ultrasound Testing

RITEC conducts Ultrasound Testing Services to detect problems in their assets such as:

Partial Discharge (Corona, Tracking, Arcing) of electrical equipment, Bearing Lubrication and Condition, Steam Trap and Valve Testing, Leak Detection of Compressed Air Systems

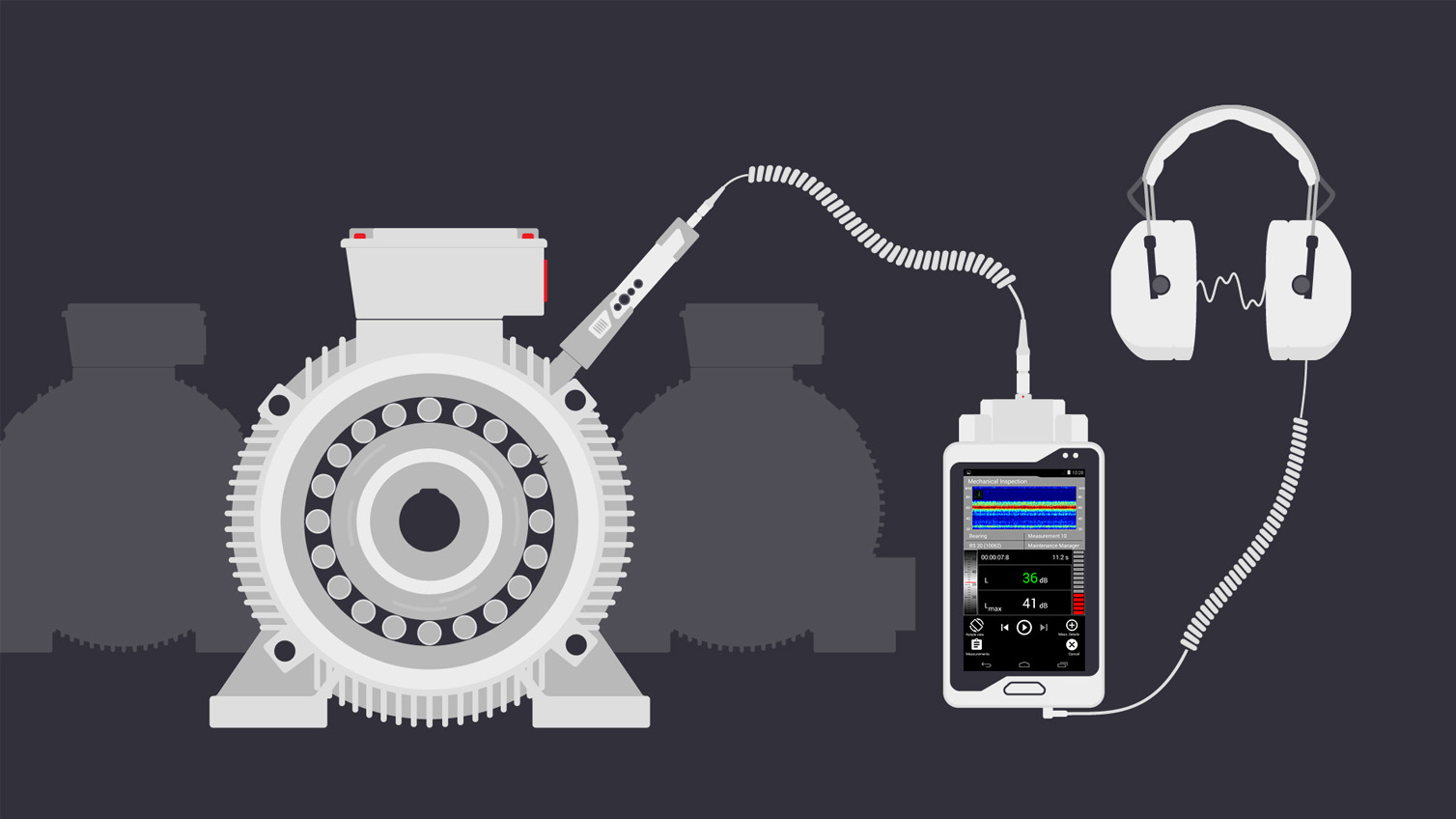

Bearing Monitoring & Lubrication

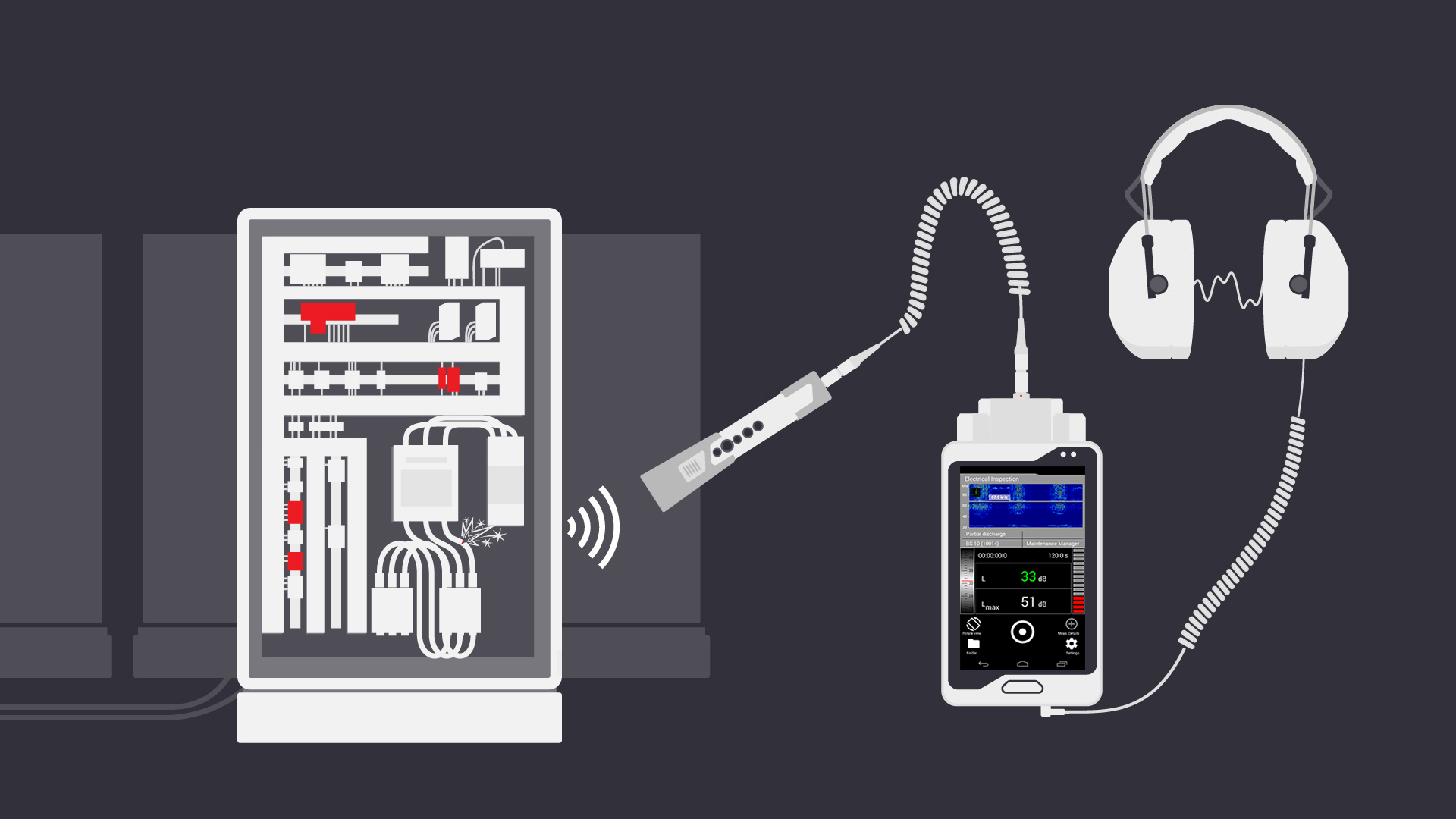

Detection of Partial Discharges

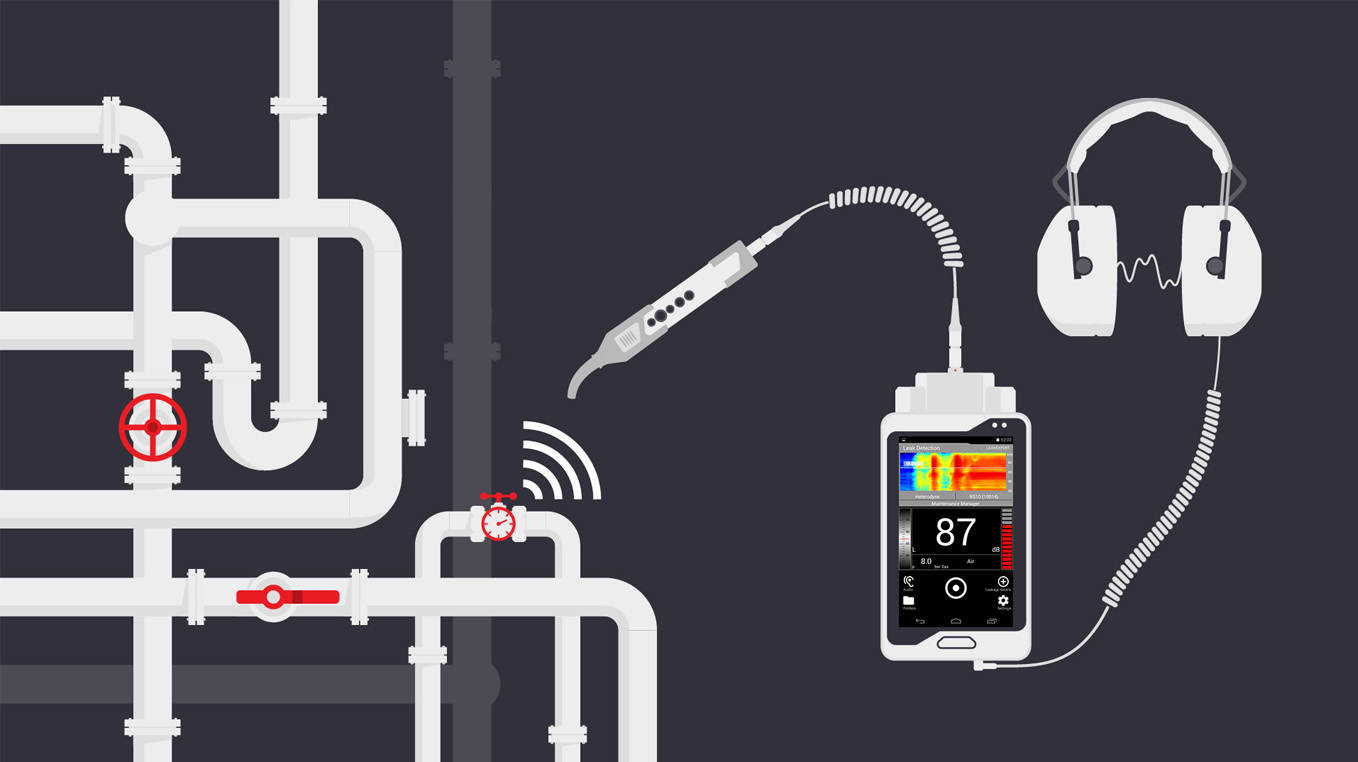

Leak Detection

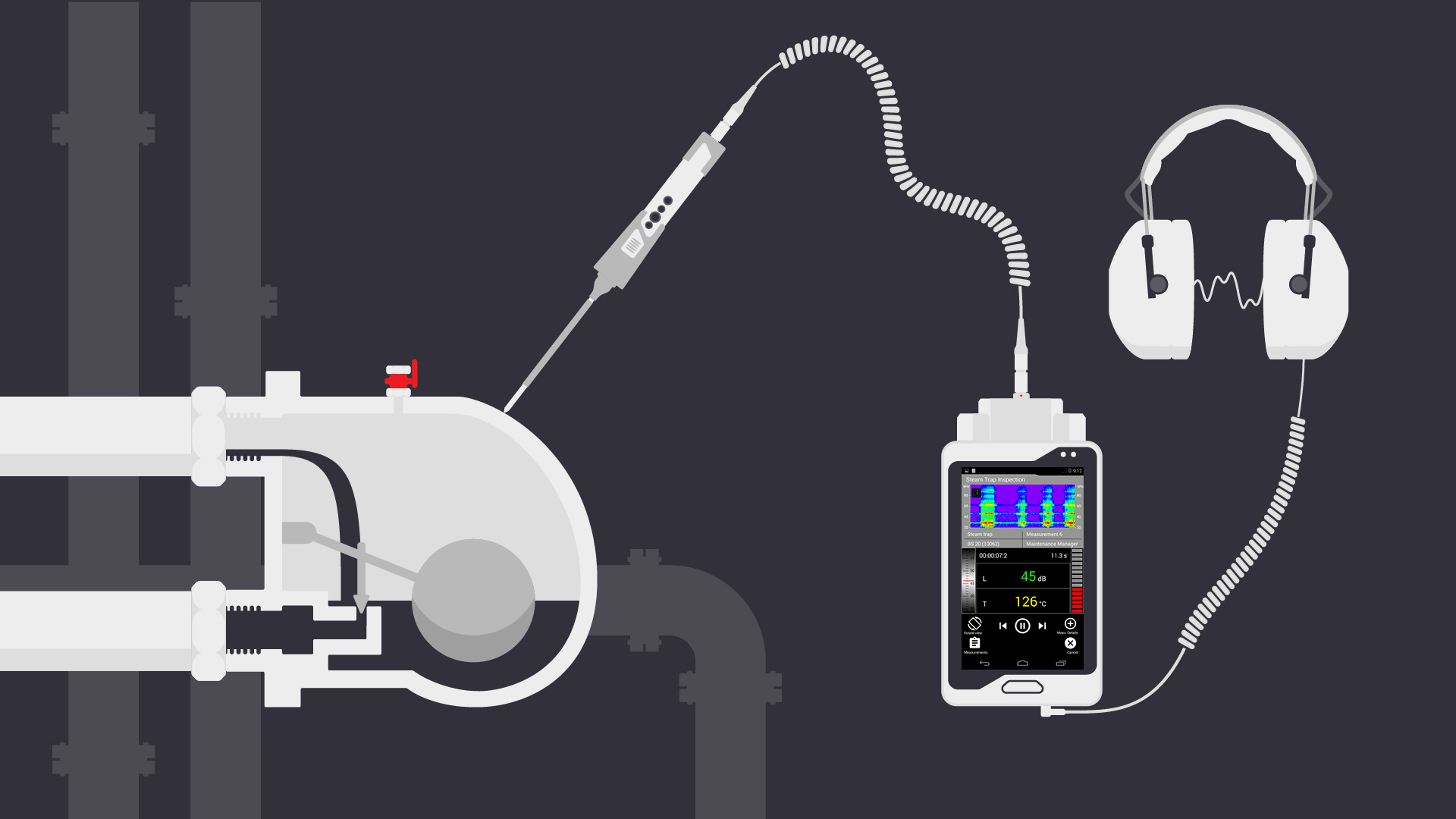

Steam Trap & Valve Inspection