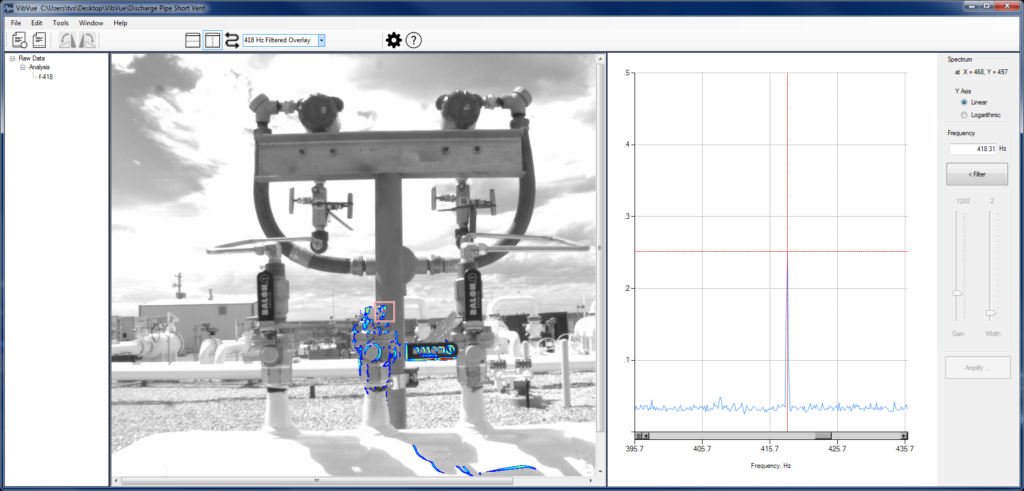

MSI VibVue Motion Magnification™ implements technology licensed from a major university in a combined software and hardware solution.

Customers can purchase VibVue™, with maintenance, support and training from MSI vibration experts, to pinpoint problems and self-diagnose the best way to solve them, or hire MSI or a Trained Service Provider, using VibVue™ as a service.

MSI is a mechanical engineering firm specializing in the design, development, troubleshooting, and application of technologies to rotating machinery and projectiles. As users of our technology, we know how it’s done, and more importantly, why.

The capabilities we’ve developed have helped us do what we do better, and we believe that VibVue™ will do the same for you.

Key Business Benefits

Faster, easier, and less error-prone diagnosis of vibration and system dynamics enable problems to be pinpointed with more certainty.

Faster, easier, and less error-prone diagnosis of vibration and system dynamics enable problems to be pinpointed with more certainty.

Enables your reliability and maintenance engineers to pinpoint problem root causes, lower maintenance costs, reduce problem resolution time and machine or plant downtime.

Enables your reliability and maintenance engineers to pinpoint problem root causes, lower maintenance costs, reduce problem resolution time and machine or plant downtime.

Implements Motion Magnification technology licensed from a major university in a combined software and hardware solution supplied and supported by MSI.

Implements Motion Magnification technology licensed from a major university in a combined software and hardware solution supplied and supported by MSI.

Two options: purchase VibVue™ to pinpoint problems and self-diagnose solutions or hire an MSI trained VibVue™ Service Provider.

Two options: purchase VibVue™ to pinpoint problems and self-diagnose solutions or hire an MSI trained VibVue™ Service Provider.

Key Business and Technical Features

Training and support provided by seasoned vibration experts

Training and support provided by seasoned vibration experts  Slows down and magnifies motion up to 1,000x

Slows down and magnifies motion up to 1,000x  Comprehensively shows pixel-level vibration data with image maps

Comprehensively shows pixel-level vibration data with image maps  Detect & display quantitative vibration levels/frequency

Detect & display quantitative vibration levels/frequency  Detection and measurement down to 0.1 mils pk-pk at 10’ FOV

Detection and measurement down to 0.1 mils pk-pk at 10’ FOV  Wide frequency range from low to >600Hz

Wide frequency range from low to >600Hz  Record and display transient "shock-like" processes

Record and display transient "shock-like" processes  PC- based, mobile, portable, no internet needed on site

PC- based, mobile, portable, no internet needed on site  Less expensive, easier to learn & use than alternatives

Less expensive, easier to learn & use than alternatives Why Choose VibVue™?

Competing products will always play catchup with one another, but MSI’s 25 years of proven expertise in the vibration field is a sustainable competitive advantage and provides VibVue™ training and support from vibration experts.

Competing products will always play catchup with one another, but MSI’s 25 years of proven expertise in the vibration field is a sustainable competitive advantage and provides VibVue™ training and support from vibration experts.

Realizing the benefit of video as a vibration analysis tool, MSI licensed some of the technology within VibVue™ from a major technical university to develop the best rotating machinery diagnostic software tool for pinpointing vibration problems faster, better and cheaper.

Realizing the benefit of video as a vibration analysis tool, MSI licensed some of the technology within VibVue™ from a major technical university to develop the best rotating machinery diagnostic software tool for pinpointing vibration problems faster, better and cheaper.

VibVue™ is just one of many vibration tools MSI has and uses. It has advantages and disadvantages compared to other tools such as ODS. For example, VibVue™ is far faster to setup and video than instrument a machine with many accelerometers, but the angle of viewing is critical because video is 2D, whereas ODS is 3D. If you can’t pinpoint your problem with VibVue™ alone, MSI support and other tools are just a call away.

VibVue™ is just one of many vibration tools MSI has and uses. It has advantages and disadvantages compared to other tools such as ODS. For example, VibVue™ is far faster to setup and video than instrument a machine with many accelerometers, but the angle of viewing is critical because video is 2D, whereas ODS is 3D. If you can’t pinpoint your problem with VibVue™ alone, MSI support and other tools are just a call away.

MSI uses VibVue™ very successfully in its own testing services as well as supplying to users and accredited vibration specialists. As a result, VibVue™ has been widely proven across industries and rotating machine types.

MSI uses VibVue™ very successfully in its own testing services as well as supplying to users and accredited vibration specialists. As a result, VibVue™ has been widely proven across industries and rotating machine types.

VibVue™ Videos of Different Rotating Machine Types