Beran PlantProtech™ Condition Monitoring Systems are in use around the world within numerous power generation companies, including coal, oil, gas-fired, nuclear and hydro. The plant items monitored include steam turbines, gas turbines and water turbines, pumps, fans, compressors and coolant circulators. Beran TransCal™ Transducer Calibration Systems are in service with many European and USA automotive, aerospace and power generation companies, along with Certified Calibration Houses, meeting the ISO 16063-21 requirement for transducer calibration.

Beran Frequency Response Analysers are employed in the verification of many aircraft and control systems.

PlantProtech™ is Beran's platform for condition monitoring of rotating machinery, built on over twenty years of industrial experience and innovation.

The PlantProtech hardware / software family is in use throughout the world, with over 300 systems currently being utilised within the power industry. The PlantProtech range is installed on Nuclear, Fossil, Hydro, CCGT and Combined Cycle industrial plant.

Originally designed to meet the requirements of the Central Electricity Generation Board (CEGB) VCM/7 specification, our PlantProtech systems have been proven to pay for themselves many times over. As user requirements have increased, the PlantProtech range has developed accordingly.

By means of continuous on-line vibration monitoring, changes in the health of the plant may be detected early. Powerful analysis tools allow the root cause of the problem to be identified, allowing operators to make crucial decisions, in many cases allowing their plant to be run with confidence at reduced load through to planned outage / scheduled maintenance.

The PlantProtech range of hardware and software products provides you with a solid foundation, which can be added to and expanded as and when required, ensuring the safety of your investments.

Real-Time: PlantProtech real-time capability allows you to analyse the machine state in real-time on-screen, as it is happening, allowing direct correlation with other Station protection equipment and process data.

Parallel Analysis: Parallel data acquisition is important to enable the user to understand the full dynamic behaviour of the machine. Beran PlantProtech Analysers feature parallel dynamic acquisition for both steady-state and variable speed plant modes, with simultaneous measuring of vibration and process parameters.

Automated vibration trip system providing API670 compliant machinery protection with integrated condition monitoring functionality

More Information

The PlantProtech PROTOR Mobile is a high-speed data acquisition and powerful diagnostic system for critical rotating machinery.

More Information

A powerful and versatile automated surveillance system for all of your strategic plant items where increased monitoring is required.

More Information

Parallel data acquisition for up to 64 vibration sensors, recommended for gas and steam turbines.

More Information

A portable 32-channel vibration analyser, built for a tough life.

More Information

Flexible data acquisition - up to 4 x 8 vibration sensors. Recommended for small turbines, fans, and feed pumps.

More Information

Visualise, trend, and diagnose the health of your plant with our easy-to-use PlantProtech™ Vision application.

More Information

Central PC data store for all your PlantProtech™ Analyser historic data.

More Information

Provides automatic file retrieval from remote sites to a central location (e.g. Technology Centre) for rapid review.

More Information

View your plant's health at a glance, with a customisable mimic.

More Information

Receive periodic updates via the automated email vibration alert interface straight to your PC inbox or mobile phone.

More Information

Description: PlantProtech™ 7600 PCMS is the latest addition to the PlantProtech™ family, building on Beran’s 40 years of machine monitoring experience to create a new generation of condition monitoring systems with the option of machinery protection.

PlantProtech™ 7600 PCMS can be configured to meet your individual requirements and can be used as:

Plant protection functionality provides an automatic trip to protect the plant in the case of high vibration exceedance. Online vibration and condition monitoring gives enhanced analysis including 24/7 real-time data and using advanced condition monitoring alarms to enable early warning of machinery health changes.

Protection and condition monitoring solutions are needed in various applications, and the PlantProtech™ 7600 PCMS modular design supports a wide range of protection applications and installations within the power generation and industrial sectors.

Designed for PlantProtech™ 7600 PCMS has been designed to comply with ISO7919 and API670 and with a lifecycle aligned with IEC 61508 Safety Integrity Level (SIL) applications.

Description: The PlantProtech PROTOR Mobile™ is the fifth generation of a multi-channel, portable system from Beran offering unrivalled capability in a compact form factor weighing less than 7kg with powerful diagnostic capability.

Key features

Designed for rotating machinery including, but not limited to

Portable diagnostic capability

A powerful vibration condition monitoring system for all your strategic plant items where both real-time and remote diagnostic monitoring is required.

Typical applications include

Summary specification

Description: Easy installation, powerful data acquisition, and versatile displays make the PlantProtech™ 720 the perfect partner for your Condition Monitoring regime.

The PlantProtech™ 720 Advanced Plant Monitor provides a powerful and versatile automated surveillance system for all of your strategic plant items where increased monitoring is required.

Designed for

Key features

Description: The PlantProtech™ 766 Analyser is a 19” rack-mount unit providing modular acquisition/analysis of up to 64 parallel channels from acceleration, velocity, proximity, and pressure sensors. This ensures high-speed condition information is acquired during both steady-state and variable speed modes - vital for accurate diagnosis of many fault conditions.

Process (DC) parameters may be acquired directly by each PlantProtech™ Analyser using either voltage or optional 4-20mA and thermocouple signals with full galvanic isolation capability. Alternatively, a connection to the plant DCS or process computer may be utilised to acquire these parameters via an electronic data link, including (for example) MODBUS, PI, OPC, or Alstom’s AMODIS.

Parallel data acquisition for up to 64 vibration sensors, recommended for gas and steam turbines.

Product notice

Discontinuing the production of the PlantProtech 766, P767 and 768 Analysers

The PlantProtech 766 Analyser has had a long and successful life, initially introduced to the market in 1993. PlantProtech P767 Portable and cost-effective low-channel count PlantProtech 768 analysers were introduced in the early 2000s as an extension to the product family.

Over 500 Beran PlantProtech 766, P767 and 768 Analysers have been supplied and installed worldwide with many remaining in continuous operation and supported by Beran for over 25 years, providing excellent long-term returns on investment. We remain committed to providing at least 10 years of product support for all shipped hardware.

Beran has continued to provide ongoing hardware and software upgrades to the Beran PlantProtech 766, P767 and 768 Analysers and associated PlantProtech Vision machinery diagnostic software throughout the product lifecycle.

Introducing Beran PlantProtech Protection and Condition Monitoring System (PCMS)

Beran has developed the new Beran PlantProtech Protection and Condition Monitoring System (PCMS) product family as a successor to the Beran PlantProtech 766, P767 and 768 family.

PlantProtech PCMS Analysers use the latest digital signal processing technology to provide a modern condition monitoring platform underpinning our ability to continue to provide reliable, robust and maintainable condition monitoring solutions for 25 years.

The PCMS platform also provides a product family enabling Beran to continuously deploy the latest advancements in condition monitoring technology into the future.

.png)

Description: The Beran PlantProtech™ 767 Analyser offers portable parallel multi‑channel plant monitoring, either for temporary usage or return‑to‑service works. Robust, fast data capture, ethernet, modem and internal solid-state data storage.

Product notice

Discontinuing the production of the PlantProtech 766, P767 and 768 Analysers

The PlantProtech 766 Analyser has had a long and successful life, initially being introduced to the market in 1993. PlantProtech P767 Portable and cost-effective low-channel count PlantProtech 768 analysers were introduced in the early 2000s as an extension to the product family.

Over 500 Beran PlantProtech 766, P767 and 768 Analysers have been supplied and installed worldwide with many remaining in continuous operation and supported by Beran for over 25 years, providing excellent long-term returns on investment. We remain committed to providing a minimum of 10 years of product support for all shipped hardware.

Beran has continued to provide ongoing hardware and software upgrades to the Beran PlantProtech 766, P767 and 768 Analysers and associated PlantProtech Vision machinery diagnostic software throughout the product lifecycle.

Introducing Beran PlantProtech Protection and Condition Monitoring System (PCMS)

Beran has developed the new Beran PlantProtech Protection and Condition Monitoring System (PCMS) product family as a successor to the Beran PlantProtech 766, P767 and 768 family.

PlantProtech PCMS Analysers use the latest digital signal processing technology to provide a modern condition monitoring platform underpinning our ability to continue to provide reliable, robust and maintainable condition monitoring solutions for the next 25 years.

The PCMS platform also provides a product family enabling Beran to continuously deploy the latest advancements in condition monitoring technology into the future.

Flexible data acquisition - up to 4 x 8 vibration sensors. Recommended for small turbines, fans, and feed pumps.

Key features

Description: The PlantProtech™ 768 Analyser is an optimised solution for smaller turbines such as those used in hydroelectric and gas-pumping installations. In addition, an alternative configuration utilising a multiplexed input option is ideal for auxiliary plant applications.

The PlantProtech™ 768 Analyser can monitor up to 4 tacho signals, 8 AC signals (32 multiplexed), 16 local DC channels (up to 256 remote), 8 digital channels, and has 8 alarm relay outputs. The multiplexed variant allows up to four non-critical plant items to be monitored cost-effectively.

Product notice

Discontinuing the production of the PlantProtech 766, P767 and 768 Analysers

The PlantProtech 766 Analyser has had a long and successful life, initially being introduced to the market in 1993. PlantProtech P767 Portable and cost-effective low-channel count PlantProtech 768 analysers were introduced in the early 2000s as an extension to the product family.

Over 500 Beran PlantProtech 766, P767 and 768 Analysers have been supplied and installed worldwide with many remaining in continuous operation and supported by Beran for over 25 years, providing excellent long-term returns on investment. We remain committed to providing a minimum of 10 years of product support for all shipped hardware.

Beran has continued to provide ongoing hardware and software upgrades to the Beran PlantProtech 766, P767 and 768 Analysers and associated PlantProtech Vision machinery diagnostic software throughout the product lifecycle.

Introducing Beran PlantProtech Protection and Condition Monitoring System (PCMS)

Beran has developed the new Beran PlantProtech Protection and Condition Monitoring System (PCMS) product family as a successor to the Beran PlantProtech 766, P767 and 768 family.

PlantProtech PCMS Analysers use the latest digital signal processing technology to provide a modern condition monitoring platform underpinning our ability to continue to provide reliable, robust and maintainable condition monitoring solutions for the next 25 years.

The PCMS platform also provides a product family enabling Beran to continuously deploy the latest advancements in condition monitoring technology into the future.

Visualise, trend, and diagnose the health of your plant with our easy-to-use PlantProtech™ Vision application.

Regardless of experience, engineers and analysts can rapidly configure hardware, analyse data, share results and pinpoint plant problems.

Description: Multiple users can access the Beran PlantProtech™ systems simultaneously and select whichever display formats suit their needs, without affecting data acquisition or other users.

Plant condition displays include Bode (stacked and multi-plot), Polar, FFT, Orbit, Time-Domain, Histogram, Waterfall, Shaft Centre Line, Real-Time Text, and Trend. Both real-time and historic data may be simultaneously displayed, including the ability to view a current run-up or run-down overlaid onto a reference or historic file.

Display types include

This software is included with:

Central PC data store for all your PlantProtech™ Analyser historic data.

Description:

The PlantProtech™ Base Station application runs on a standard Microsoft Windows platform, and is scalable from a laptop to company-wide installation.

PlantProtech™ files may be analysed using PlantProtech™ Vision.

Data from multiple PlantProtech Analysers may be stored and then accessed by many users through a single Base Station installation.

The PlantProtech™ Base Station application runs on a standard Microsoft Windows platform, and is scalable from a laptop to company-wide installation.

PlantProtech™ files may be analysed using PlantProtech™ Vision.

Data from multiple PlantProtech Analysers may be stored and then accessed by many users through a single Base Station installation.

This software is included with:

The PlantProtech™ Auto Archive Downloader provides automatic file retrieval from remote sites to a central location (e.g. Technology Centre) for rapid review.

The application has the additional dual functionality of data archiving, either to local IT infrastructure or to a central Technology Centre, etc.

Description: The PlantProtech™ Auto Archive Downloader application has been designed to automatically retrieve data files and alarm logs from Beran PlantProtech™ Analysers, either on demand or at a scheduled time. The retrieved data from multiple PlantProtech™ Analysers may then be:

The Auto Archive Downloader is scalable from one PlantProtech™ Analyser to fleet-wide installation, and may be purchased as a single application to provide either archiving or data file downloading capability or both.

The archiving function automatically downloads PlantProtech™ Analyser data files to a central location and manages the internal data storage.

The PlantProtech™ Auto Archive Downloader operates on a standard Microsoft Windows platform, and the application supports the download of files via network or dial-up modem connections.

Specified at the time of purchase, there are two main modes of functionality:

System requirements

View your plant's health at a glance, with a customisable mimic.

Description: A mimic, customised to suit the plant monitored, provides an overall pictorial that delivers an easy-to-use summary of the current vibration levels and process parameters, allowing the operator to determine precisely which area to investigate further.

Colour changes inform the operator if any vibration channel or process parameter moves from a normal operating condition into alert or alarm status. The operator can then access either a real-time display or view the alarm log to assist in determining plant condition.

Receive periodic updates from Beran PlantProtech™ Analysers via the automated Email Vibration Alert interface straight to your PC inbox or mobile phone. Stay in touch 24/7, wherever you are, and remain informed about any changes in the vibration status or condition of your machine, assisting in the prevention of potential issues before they occur.

Description: The Email Vibration Alert is an optional software interface for the Beran PlantProtech™ Analyser, designed to provide users with the automated email alerts of machine alarm and system health status.

The Email Vibration Alert interface sends e-mails detailing alarm and system status to a configured e-mail address using industry-standard SMTP protocols. The alarm and system status e-mails may be received by the end-user using a standard e-mail client (e.g. Microsoft® Office Outlook®), or alternatively, they may be received and processed by a user-customised data screening application.

The Email Vibration Alert Interface monitors the alarm and/or system logs of any Beran PlantProtech Analyser. New log messages are sent via an e-mail server to a nominated e-mail address. Separate e-mails are sent for each log monitored from each installed PlantProtech Analyser. The E-mail Vibration Alert Interface may be configured to check for new log entries at regular intervals, ranging from once every five minutes to once a day. Additionally, a “summary” facility may be configured to resend all log messages once a day at a specified time, or once a month on a specified day and time.

The Email Vibration Alert Interface is installed and commissioned by Beran personnel. At the time of installation, the E-mail Vibration Alert Interface will be configured by Beran to the user’s requirements. The E-mail Vibration Alert Interface may be installed and commissioned remotely via a modem connection to the Beran PlantProtech Analyser, with minimal disruption to normal operation.

System requirements

Azima DLI, a Fluke Reliability company, is the global leader in vibration monitoring, AI-powered analytics software, and expert vibration analyst services. The company was founded as DLI Engineering in 1966 and acquired by Fluke Reliability in 2023.

TRIO offers key benefits for your maintenance program

Versatility: Different sizes of tablet vibration data collectors to meet your needs

Safety: TRIO controller can operate at safe distances giving distance between the operator and rotating machinery with Bluetooth®

Robust: Four simultaneous channels of vibration data plus dedicated tachometer provides advanced data acquisition

Effective: Expert automated diagnostic integration delivers solutions to managers and other decision makers

Modular design lowers the overall cost of ownership

A dynamic computerized system in a mobile industrial package focused on ergonomics, efficiency, and safety.

Inexpensive hardware replacement

Automatic software updates

Integration with other PdM applications

Machine health history onboard

Always-On Equipment Monitoring Keeps You at Uptime All the Time

More Information

Quick and easy to install, our wireless vibration sensors provide real-time data and actionable insights to prevent downtime from day one.

What makes Azima wireless sensors different?

With Azima Accel 310™ wireless vibration sensors, get 24/7 insight into the equipment you’re monitoring. Make informed decisions to prevent product defects and downtime.

Quick and Easy Wireless Sensor Installation

Time is money, so the last thing you need is a complicated setup process. Accel 310™ wireless vibration sensors are easily mounted on assets or components and will start capturing data within seconds.

Vibration Experts at Your Service

Our ISO Level II-IV certified analysts help take your condition monitoring program to the next level. Experts are always available to help your team meet uptime, compliance, and cost-avoidance goals.

AI-Powered Analytics for Ahead-of-Time Maintenance

WATCHMAN analytics software uses advanced AI to convert sensor data into easy-to-understand fault diagnosis and clear, actionable repair recommendations. That way you can foresee and prevent failures months in advance.

Quick, actionable data at your fingertips. Keeping your equipment running at its best has never been easier.

What makes Azima handheld analyzers different?

Azima handheld vibration analyzers are Hazloc rated as standard, user-friendly, ergonomic, and offer advanced AI diagnostics for quick and accurate fault detection.

Rent Azima’s handheld vibration analyzers

Not ready or able to commit to purchase? Why not rent and still benefit from the advanced AI diagnostics capability that the Azima diagnostic software has to offer.

Vibration Testing, Made Ridiculously Easy

Designed for you. Handheld TRIO™ vibration analyzers are built with comfort and ease of use in mind, allowing for straightforward data collection without the need for specialized training.

Capture Vibration Data, Export, Done!

Simplify your workflow. Azima TRIO™ handheld vibration analyzers do away with time-intensive traditional data collection processes by using automated collection and diagnostics.

Diagnose Faults in Seconds. Act in Minutes.

Improve predictive maintenance with AI-driven diagnostics. Azima WATCHMAN diagnostic software analyzes the data from TRIO™ devices and gives technicians prioritized repair recommendations for rotating machinery.

Watch As Reliability Soars With The Help Of Our Vibration Experts

Get access to the best vibration analysts in the industry. Our service professionals work with your engineers to analyze vibration data, improve the effectiveness of your condition monitoring program, and speed time to value.

High-performance Online Condition Monitoring system for critical assets

What makes Azima's condition monitoring solution different?

With real-time data, AI diagnostics, and expert vibration analysis in one convenient package, you can cut the guesswork and confidently rely on Azima for all your condition monitoring needs. Let us handle the diagnostics so that you can direct maintenance efforts where they’re needed most — ensuring that each asset works longer and more efficiently than ever before.

Condition Monitoring for the Most Complex Assets

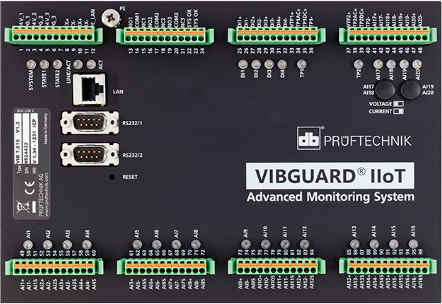

Fast, reliable, and powerful, VIBGUARD® IIOT Online Condition Monitoring system provides continuous monitoring and protection for the most complex systems against unplanned downtimes with the highest-quality data capture.

Turn Online Condition Monitoring Into Action

Gain control of critical asset uptime. by analyzing data from VIBGUARD®. It only takes a few minutes for our AI-powered diagnostic engine to produce a fault diagnosis, repair priority, and recommended repair actions.

Vibration Experts at Your Service

Rely on the unmatched expertise of our vibration analysts. They reduce any guesswork involved with interpreting complicated vibration data, giving your team the confidence to take precise, informed actions where it’s most critical and impactful.

Condition Monitoring That Triples The Benefits: More Production, Longer Life, Less Cost

Our customers have unlocked a 2% boost in production capacity, 10% longer equipment life, and 30% lower program costs with our integrated solution of predictive maintenance hardware, software, and expert services.

For over thirty years the Erbessd family of companies has been leading the industry in providing intuitive, easy-to-use dynamic balancing & vibration analysis products that make our customers’ jobs easier. Rugged, repeatable, and reliable Erbessd products exceed industry recognized standards & more importantly exceed our customers standards.

There’s finally a choice in Vibration Analysis & Dynamic Balancing that doesn’t consume your budget. Our systems are based on the familiar Microsoft Windows® operating system that operate in a fully rugged & industrial tablet form factor. Offering advanced features such as Cross-Channel Phase & ODS (Operational Deflection Shape) out of the box without any added costs, our products are built to delight.

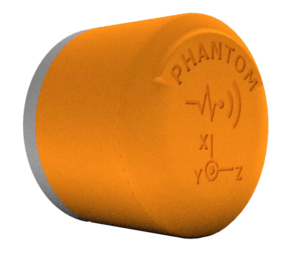

Phantom is a wireless vibration monitoring system that integrates other parameters such as temperature, current, RPM and speed into a single diagnosis system.

In addition, our sensors have a battery life that lasts enough to take up to 100,000 measurements andthey are very easy to install.

Equally important, Phantom can send data to a local database or to our cloud-based system, EIAnalytic.

At any moment, you can keep track of your machinery using any device such as a smartphone, computer or tablet.

Why Phantom Vibration Monitoring?

Our vibration and condition monitoring system will help you to predict machine failures and save huge amount of costs due to non-programmed down times in production.

These are a sample of the most common failures that can be identified by our condition monitoring system:

Easy Installation

Wireless Technology in Vibration Monitoring has been developed in response to unmet needs of simplicity, for installation as for industrial cabling requirements. Our wireless sensors are very easy to install.

The connection of the sensors to the Gateway will be done automatically without any intervention.

Wireless Technology

Our vibration monitoring system uses ultra-low power BLE 5.0 technology.

Therefore, our wireless sensors can reach a useful life enought to take up to 100,000 measurements without the need to change the battery.

Additionally, this technology is the most reliable in the market, providing distance ranges of up to 1 km with no obstacles and 250 meters in line-of-sight with competing signals.

Furthermore, our wireless sensors have been successfully tested, even inside grounded metal cabinets, reaching distances of up to 60 meters. One of our clients even stated: “Phantom is the magic unicorn system we’ve been looking for.”

Exploring the advantages

Convenience: This is the most attractive of all the wireless sensors attributes.

Sometimes it is just too difficult to place sensors and wires all the way from a machine to a control room. Because the sensors does away with the cables and power requirements, wireless sensors can be placed anywhere within the range.

Reasonable Cost: If you have a PDA or a celular phone, you easily understand why going wireless is much more cost effective than wires. Cabling long distances can be quite expensive compared to wireless sensors.

Ease of use: Well, it is really easy to use and install. All complex parts are already sorted out internally, but of course, as for everything else, there is a learning curve.

Accessibility: Certain places on machines are simply not accessible with wires. Wireless Sensores might be a solution for that.

Security: The signal from the Phantom sensors is encrypted which ensures the reliability of the information and the security of your data.

– New – Modbus Universal Communication

Phantom Wireless Sensors include now Modbus TCP/IP which is a widely known and used universal communication protocol for industrial applications.

Thus, making them compatible with any PLC, Scada system or any other Modbus TCP/IP communicating software.

Applications:

Good vibration monitoring techniques require complete and accurate triaxial accelerometers as well. Hence being able to send 3 simultaneous FFT and Time waveform recordings for all three axis at once. We have improved to the maximum the energy consumption resulting in life batteries enough to take up to 100,000 measurements.. Additionally our wireless accelerometers can wake up on high vibration levels to send data and alarms. As an additional value, all of our wireless accelerometers have a built-in integrator so they can, internally, calculate velocity parameters for alarms. This way, RMS values can be sent as well with a selectable periodicity. Internal temperature is measured as well.

Send data Only when the Machine is Running

Phantom Vibration sensor can locally communicate with Phantom RPM sensor or Phantom Amperage sensor to evaluate if the machine is running. Hence avoiding irrelevant data. Ranges of RPM and Amperage can be configured to make the sensor record only within a desired condition.

Meet Phantom Vibration Sensor:

Temperature

All of our wireless sensors include temperature, however, we added wireless temperature sensors dedicated to measure extreme temperatures.

Wireless Amperage Sensor

Phantom includes non-invasive wireless current sensors to monitor power consumption from your electric motors. Moreover, each sensor includes 3 simultaneous channels to measure each of the 3 motor’s phases. Our Amperage wireless sensor includes internal temperature as well.

Wireless RPM sensor

We also created an RPM sensor for our vibration monitoring system. This sensor integrates your machine’s rotational speed to the overall analysis. As a result, you will be able to compare vibration, temperature and power consumption at different speeds.

General-Purpose Wireless Sensor Adapter

Our General Purpose Wireless sensor adapters are able to monitor virtually any type of signal coming from your own devices, such as:

General Purpose Wireless sensor adapter comes with a LEMO connector with capability of up to 4 channels or 2 differential inputs. Inputs can measure 0 to 5 volts.

4-20 mA Wireless Sensor Adapter

As a variation we created a 4-20 mA Wireless sensors adapter. The 24-bit 4-20 mA Input interfaces with any sensor providing a 4-20 mA signal to implement your data into an integrated wireless system. This adapter features 4 channels non-switched battery-saving input that extends the life of the internal battery. It also offers digital filtering which improves measurement accuracy with 10 to 1024 readings/samples and 60 Hz noise rejection.

Kit Content

Our Vibration Monitoring system includes the most powerfull DigivibeMX versión. You can choose between the next sensor:

Includes:

No Software Costs

Our Vibration Monitoring System includes the powerful vibration analysis software DigivibeMX® without any limitation. With DigivibeMX®, you can perform a deep analysis on each spectrum and signal, as well as identify the tendency of vibrations.

Vibration Monitoring Online Cloud | EIAnalytic

EIAnalytic is our cloud-based database system for Phantom®. It provides simple accessibility through a web browser or mobile app. Additionally, our cloud allows direct connections from the DigivibeMX® for data management, as if it were on its own hard drive.

QR Codes for your machines

Scan the code of a machine and you will get its condition. If you walk through the plant or factory and you wish to know the status of a machine, you only need to scan its code with your smartphone. Our Wiser Vibe app will display all the information related to your machine. Truly simple monitoring system!

Automatic Learning

Our vibration monitoring system includes a powerful learning protocol for your machinery vibration. During a period (7 days by default), Phantom will learn from the vibration of your machine to identify a “Normal” behavior.

Phantom includes 3 types of learning:

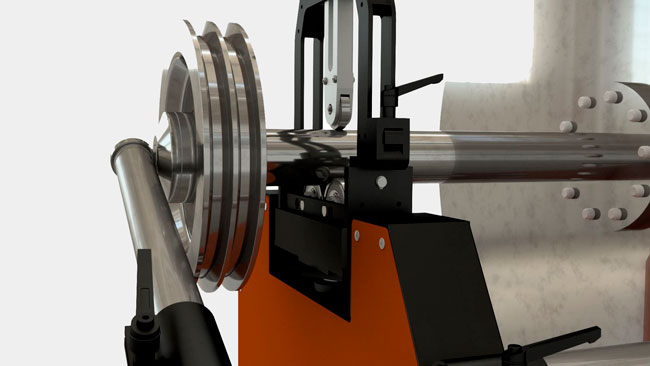

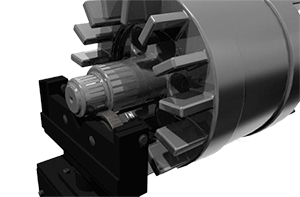

What is a Balancing Machine?

A Balancing Machine is an instrument designed to measure and eliminate the imbalance mass of a rotor. In fact, Dynamic Balancing Machines spin the rotor to detect the center of mass through vibration sensors. These vibration sensors are usually accelerometers. Finally, simple calculations will indicate the position of the correction weights.

Imbalance / Unbalance

The imbalance is the distance between the center of rotation and the center of mass. Hence, it is said that the closer these 2 points are, the lower the amount of imbalance.

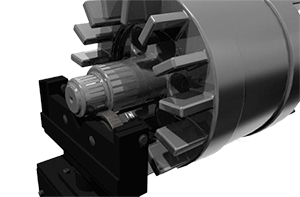

The EI-30 Balancing Machine is ideal for turbochargers & assemblies, as well as small rotors. It is a fully portable balancer that can be placed on any workbench. With the help of this balancer you can make efficient and quick balancing jobs with high accuracy.

Turbo Balancing Machine Features

Soft Bearing Balancing Machine – Accurate

Portable Balancing Software DigivibeMX® M10 included

Easy Balancing – Balance More

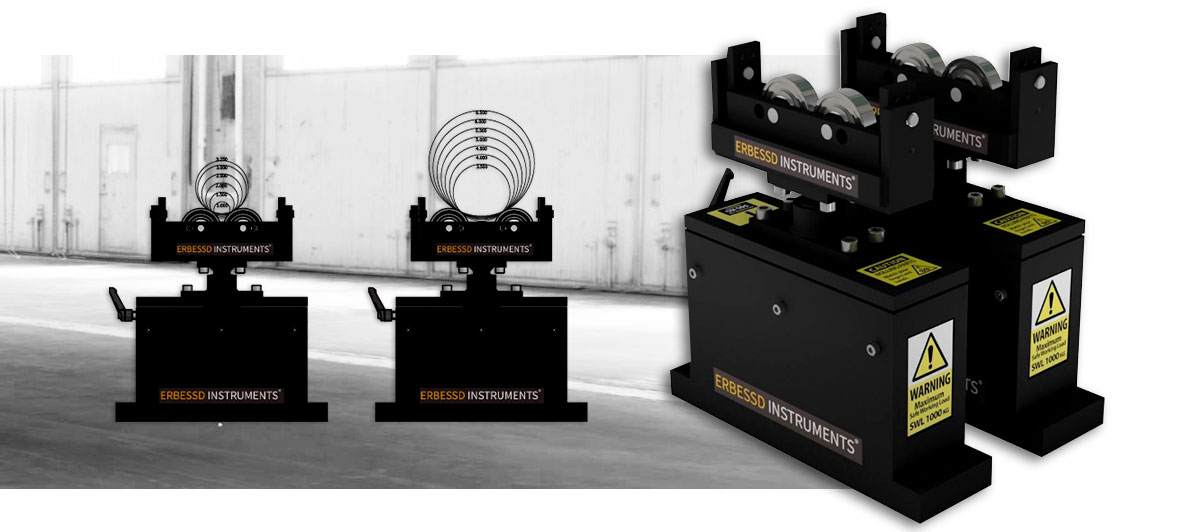

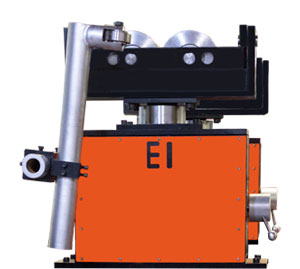

The EI-300 Dynamic Balancing Machine is designed to balance rotors of any type accurately. The length of its bench allows balancing rotors up to 2 meters long to be mounted. Additionally, EI-300 will allow you to make overhung balancing thanks to its negative supports (optional).

Features

EI-300 uses light and resistant materials for the SBS System in order to reduce inertia.

Equiped with Soft Bearing Suspension System

DigivibeMX® M10 included

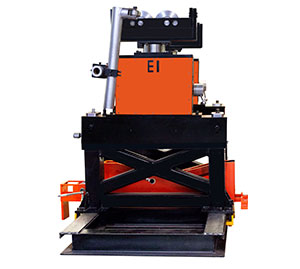

The EI-1000 is one of the most versatile balancing machine, allowing you to balance small rotors to up to 1-ton rotors. This versatility makes this balancer the best seller as it adapts to most of the requirements of rotors in an average workshop. With the help of this balancer you can perform fast and accurate balancing jobs.

.jpg)

Features

EI-1000 uses light and resistant materials for the SBS System in order to reduce inertia.

Equiped with Soft Bearing Suspension System

DigivibeMX® M10 included

EI-2000 is a balancing machine for medium and large size rotors. This balancer will allow you to balance rotors from 7 kg to 2 tons. Additionally, this balancer has the option for overhung rotors. You can get an extension of the base frame to reach rotors longer than 4 meters.

Features

EI-2000 uses light and resistant materials for the SBS System in order to reduce inertia.

Equiped with Soft Bearing Suspension System

DigivibeMX® M10 included

Balancing Machine EI-4500 has been designed for heavy rotors. This machine will allow you to balance rotors from 150 kg to 4.5 tons. As well as all of our machines, this balancer has the option for overhung rotors. You can get an extension of the base frame to reach rotors longer than 6 meters if needed.

Balancing Machine EI-6000 has been designed for heavy rotors. This machine will allow you to balance rotors from 150 kg to 6 tons. As well as all of our machines, this balancer has the option for overhung rotors. You can get an extension of the base frame to reach rotors longer than 6 meters if needed.

Within the range of big balancing machines EI-10T has the biggest versatility. This machine will allow you to balance rotors from 200 kg to 10 tons. Extensions for super large rotors are available as well as different roller work supports for smaller rotors.

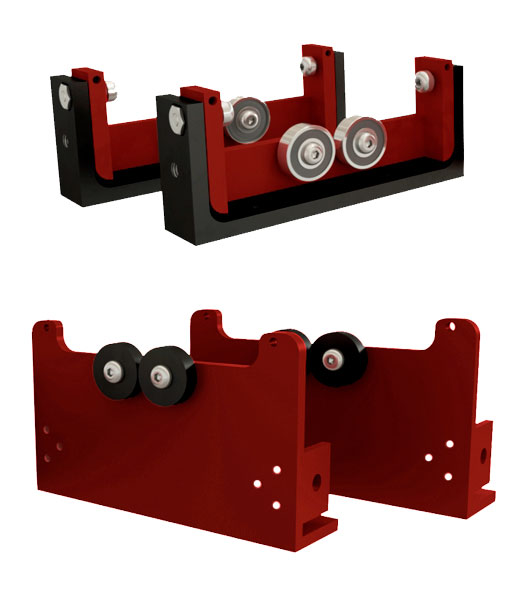

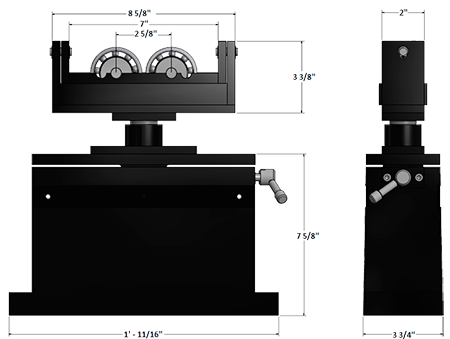

Build your own Turbo Balancing Machine, whether it is on the base of your milling machine or on a station of your own. The SBS-30 Soft Bearing Suspensions will help you make a very versatile balancer with the high accuracy of soft bearing systems. The drawings for the design of the machine can be downloaded here.

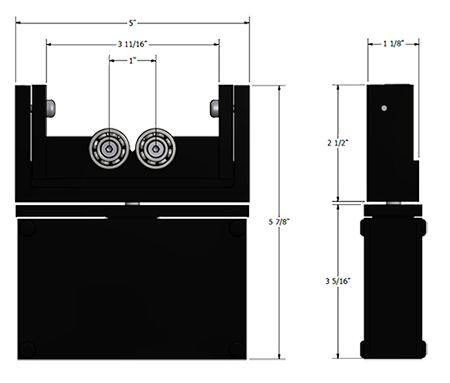

Features & Advantages

| Max Load | 30 kg (66 lb) Pair / 15 kg (33 lb) Each |

| Dimensions (L x W x H) | 127 x 28.58 x 150 mm (5 x 1.125 x 5.875 in) |

| Weight | 0.9 kg (2 lb) / Unit |

| Max Axial Load | 2.21 N (0.50 lbf) |

| Min Bearings Surface contact | 8 mm (0.313 in) |

| Max Radial Displacement | 15 mm (0.600 in) |

| Max Shaft Diameter in supports | 152 mm (6 in) |

| Lock System | Yes |

| Elevation Screw | 12.70 mm (0.500 in) |

| Accelerometer | Optional |

Accessories & Spare Parts

It’s an accessory for SBS required when balancing rotors are mounted on cantilever and/or to secure rotors with high levels of vibration, like crankshafts. Each support includes bearings and has adjustable height. Its dimensions may vary depending on the bearing suspensions.

DigivibeMX is the family of devices that allows you to perform vibration analysis and dynamic balancing with more functions in the market. From simple vibration analysis to complex 3D ODS vibration simulations.

Including magnetic base.

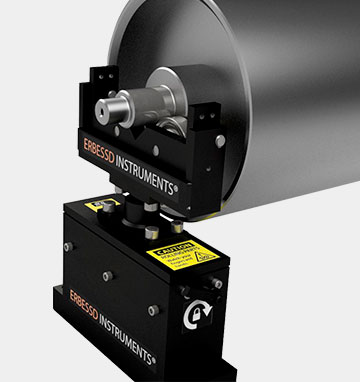

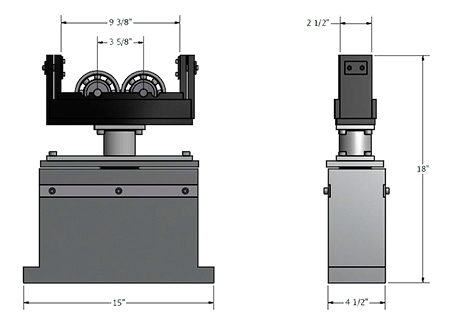

The SBS-300 Soft Bearing Suspensions will help you build your own Balancing Machine. With these Soft Bearing Suspensions, you can make a very versatile balancer without sacrificing the high accuracy of soft bearing systems. The drawings for the design of the machine can be downloaded here.

Features & Advantages

The SBS-300 can support up to 300 kg (150 kg each support), and it allows shaft diameters of 152 mm (6 in) at journal diameter. Also has an elevator screw to adjust the position in case the tracks rotor supports have different diameters up to 25.4 mm (1 in) and a swinging movement for auto-alignment.

Balancings are done at higher frequencies than the suspension’s resonance frequency. With all these characteristics, the system allows the rotor to spin around its gravity center instead of its geometric center.

The rolling elements have a swing system with a pitch up to 10°. This way the SBS-300 gets aligned automatically with the shaft to prevent distortion on the shaft’s rolling surface.

SBS-300 was designed with thin cantilever roller work supports to allow mounting rotors with very short shafts.

| Max Load | 300 kg (660 lb) Pair / 150 kg (330 lb) Each |

| Dimensions (L x W x H) | 260 x 76 x 309 mm (10.250 x 3 x 12.1875 in) |

| Weight | 9.5 kg (21 lb) / Unit |

| Max Axial Load | 22.1 N (4.96 lbf) |

| Min Bearings Surface contact | 16 mm (0.630 in) |

| Max Shaft Diameter in supports | 63.5 mm (2.5 in) |

| Lock System | No |

| Elevation Screw | No |

| Accelerometer | Optional |

Accessories & Spare Parts

It’s an accessory for SBS required when rotors are mounted on cantilever and/or to secure rotors with high levels of vibration, like crankshafts. Each support includes bearings and has adjustable height. Its dimensions may vary depending on the bearing suspensions model.

DigivibeMX is the family of devices that allows you to perform vibration analisis and dynamic balancing (depending of the DigivibeMX version) with more functions in the market. From simple Vibration analysis to complex 3D ODS vibration simulations.

Including magnetic base.

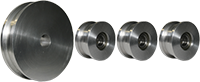

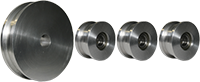

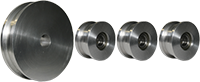

Set of 3 bearing pulleys and 1 driver pulley for EI-300 balancing machine.

With the SBS-1000 Soft Bearing Suspensions you will manufacture one of the most versatile balancing machines available. The SBS-1000 allow you to balance small rotors from 3 kg to medium sized rotors of 1000 kg. Balancing will be done quickly and accurately. You can download the drawings for this balancer here.

Features & Advantages

SBS-1000 allows you to make very high precision balancings on almost any kind of rotating parts.

SBS-1000 is a balancing support kit intended to provide you a way to build your own balancing machine at a very low cost with very high performances.

The SBS-1000 can support up to 1000 kg (500 kg each support), and with its 2 roller positions it allows shaft diameters of 152 mm (6 in). Also has an elevator screw to adjust the position in case the tracks rotor supports have different diameters up to 25.4 mm (1 in) and a swinging movement for auto-alignment.

Balancings are done at higher frequencies than the suspension’s resonance frequency. With all these characteristics, the system allows the rotor to spin around its gravity center instead of its geometric center.

The rolling elements have a swing system with a pitch up to 10°. This way the SBS-1000 gets aligned automatically with the shaft to prevent distortion on the shaft’s rolling surface.

SBS-1000 was designed with thin cantilever roller work supports to allow mounting rotors with very short shafts.

| Max Load | 1,000 kg (2,200 lb) Pair / 500 kg (1,100 lb) Each |

| Dimensions (L x W x H) | 127 x 28.58 x 150 mm (5 x 1.125 x 5.875 in) |

| Weight | 20 kg (44 lb) / Unit |

| Max Axial Load | 76.5 N (16.53 lbf) |

| Min Bearings Surface contact | 16 mm (0.630 in) |

| Max Radial Displacement | 20 mm (0.788 in) |

| Max Shaft Diameter in supports | 152 mm (6 in) |

| Lock System | Yes |

| Elevation Screw | 12.70 mm (0.500 in) |

| Accelerometer | Optional |

Accessories & Spare Parts

It’s an accessory for SBS required when balancing rotors are mounted on cantilever and/or to secure rotors with high levels of vibration, like crankshafts. Each support includes bearings and has adjustable height. Its dimensions may vary depending on the bearing suspensions.

DigivibeMX is the family of devices that allows you to perform vibration analisis and dynamic balancing (depending of the DigivibeMX version) with more functions in the market. From simple Vibration analysis to complex 3D ODS vibration simulations.

Including magnetic base.

Set of 3 bearing pulleys and 1 driver pulley for EI-1000 balancing machine.

The SBS-2000 allow you to create a balancer for large rotors up to 2000 kg. This balancing machine will allow you to perform balancing jobs in 2 planes as well as in a single plane and cantilever. Manufacture the bed for the desired length, this way you will not be limited in the size of the rotor.

Features & Advantages

SBS-2000 are designed with centered bearings for stable rotor support.

| Max Load | 2,000 kg (4,400 lb) Pair / 1,000 kg (2,200 lb) Each |

| Dimensions (L x W x H) | 127 x 28.58 x 150 mm (5 x 1.125 x 5.875 in) |

| Weight | 35 kg (77 lb) / Unit |

| Max Axial Load | 147 N (33 lbf) |

| Min Bearings Surface contact | 38 mm (1.5 in) |

| Max Radial Displacement | 25.4 mm (1 in) |

| Max Shaft Diameter in supports | 152 mm (6 in) |

| Lock System | Yes |

| Elevation Screw | 12.70 mm (0.500 in) |

| Accelerometer | Optional |

Accessories & Spare Parts

It’s an accessory for SBS required when balancing rotors are mounted on cantilever and/or to secure rotors with high levels of vibration, like crankshafts. Each support includes bearings and has adjustable height. Its dimensions may vary depending on the bearing suspensions.

DigivibeMX is the family of devices that allows you to perform vibration analisis and dynamic balancing (depending of the DigivibeMX version) with more functions in the market. From simple Vibration analysis to complex 3D ODS vibration simulations.

Including magnetic base.

Set of 3 bearing pulleys and 1 driver pulley for EI-2000 Balancing Machine.

The SBS-4500 will allow you to balance large rotors. The base of this machine is simple to manufacture, and you should not have any problem starting to work on it in a short time. SBS-4500 features the well known precision of soft bearing balancing machines at a very affordable price.

The SBS-6000 will allow you to balance large rotors. The base of this machine is simple to manufacture, and you should not have any problem starting to work on it in a short time. SBS-6000 features the well known precision of soft bearing balancing machines at a very affordable price.

The SBS-10T will allow you to balance large rotors. The frame for this machine is simple to manufacture, in a short time you should be up and running. SBS-10T features the well known precision of soft bearing balancing machines at a very affordable price.

SBS-25T Suspensions are big stuff. This balancing machine will allow you to balance very large rotors. The frame for this machine is also easy to manufacture using the drawings provided by us. SBS-25T features the very well known precision of soft bearing balancing machines at a very affordable price.

Hofmann Mess- und Auswuchttechnik is the successor of the company Gebrüder Hofmann KG. We combine 75 years of experience in balancing and vibration technology with modern management and continuous innovation. As part of the Dionys Hofmann Group of Companies we are able to invest intensively in research & development and provide our customers a comprehensive local service with several international facilities.

Is the basic vibration meter for measuring the effective vibration velocity veff (rms) according to DIN ISO 10816-3 or the vibration acceleration and the rolling bearing condition gSP according to the shock pulse method.

Using the integrated speed sensor allows you to determine a rotating machine's speed.

As an option the instrument may be used as a temperature meter or for the adjustment of the belt tension in belt drives.

Features:

Applications:

| Measurement Range | |

|---|---|

| Overall Vibration | 0 - 999.9 (mm/s)eff or (m/s²)eff |

| Rolling Bearing Vibration | 0 - 999.9 gSP |

| Speed | 30 - 200,000 1/min (0.5 - 3,333 Hz) |

| Temperature | 0 - 200 °C / 32 - 392 °F |

| Transducers | Acceleration sensor HMA 1140,100 mV/g Integrated laser speed sensor |

| Dimensions | 80 mm x 160 mm x 40 mm |

| Weight | 350 grams |

| Battery Operation Time | min. 6 Hours |

Is the state-of-the-art field balancing instrument for balancing rotating machinery in one or two planes under operating conditions.

Features:

Applications:

| Measurement Range | |

|---|---|

| Overall Vibration | 0 - 999.9 (mm/s)eff or (m/s²)eff |

| Rolling Bearing Vibration | 0 - 999.9 gSP |

| Speed | 30 - 200,000 1/min (0.5 - 3,333 Hz) |

| Temperature | 0 - 200 °C / 32 - 392 °F |

| Transducers | Acceleration sensor HMA 1140,100 mV/g Integrated laser speed sensor |

| Dimensions | 80 mm x 160 mm x 40 mm |

| Weight | 350 grams |

| Battery Operation Time | min. 6 Hours |

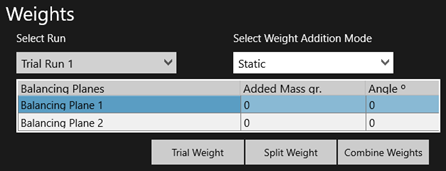

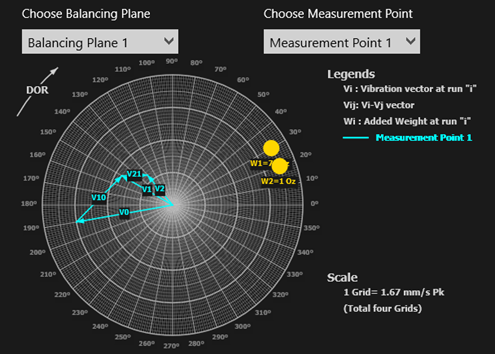

By listening to our customers, an enhanced user friendly interface, and fully loaded options and procedures, have been implemented in the RITEC Balancing Software V2.0 has been developed and released. A smooth and intuitive operation of the software promises a hassle-free balancing job.

RITEC Balancing Software V2.0 is the most user-friendly advanced balancing software on the market. It can perform balancing calculations for:

Egypt: +20-(0)2-2358-2875

Fax: +20-(0)2-2358-2654

KSA: +966 56 536 8040

UAE: +971 50 302 1959

Egypt: 63, Road 14, Maadi, Cairo, Egypt, 11431

KSA: King Fahd Bin Abdulaziz Road, Al-Khobar Mall, Office 312, Al-Khobar, Saudia Arabia

UAE: Building A3, Floor 3, DWC, Dubai, UAE

Egypt: ritec@ritec-eg.com

Sales: sales@ritec-eg.com

KSA/UAE: ritec@ritecarabia.com