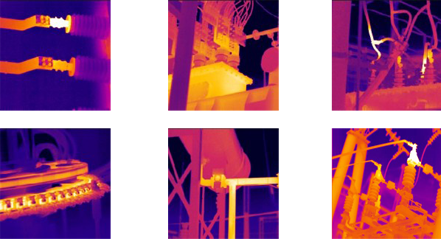

Thermal Imaging

Heat is often a symptom of eminent machine/equipment failure or malfunction. A non-contact infrared imager can be used to quickly obtain a multipoint temperature profile that can easily be assessed.

Thermal imaging allows the easy inspection of: Live electrical connections that would be dangerous to touch, insulated but hot electrical circuits, Running electrical or mechanical equipment, Targets that can be contaminated or altered by being touched, and Heating and cooling equipment.

Thermal Imaging can be used for Building Envelopes Evaluations: for conductive and convective energy losses due to insulation issues and openings in the envelope, water leaks in roofs, walls, foundation and security issues, and pest infestation.

All surveys conform with British Standard 7671.

NFPA 70B states that "routine infrared inspections of energized electrical systems should be performed annually prior to shutdown. More frequent infrared inspections, for example, quarterly or semiannually, should be performed where warranted by loss experience, installation of new electrical equipment, or changes in environmental, operational, or load conditions.”

RITEC's team of specialists conducts thermography surveys. Annual Surveys are important for Electrical Equipment: Switchboards, Panel Boards, Panel Boxes, PDU's, Bus Ducts, Power Cabling, Control Panels, Cable Terminations, Transformers (air and oil), Fuse Disconnects and holders.

Electrical Equipment:

Mechanical Equipment: