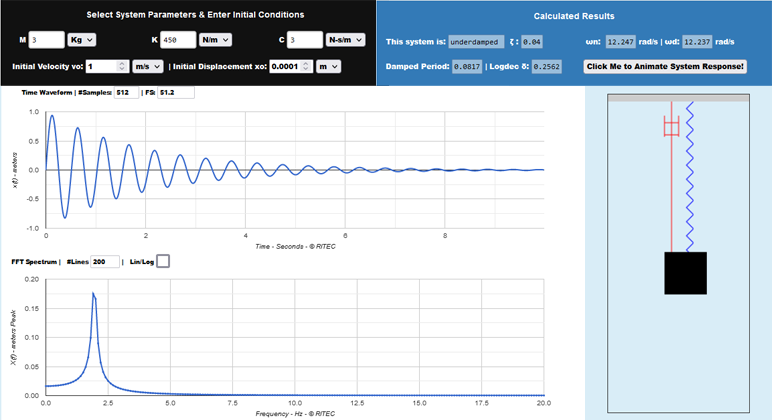

Calculate & Animate the effects of mass, stiffness, damping, and initial conditions on the free vibrations of a single-degree of freedom, second order system.

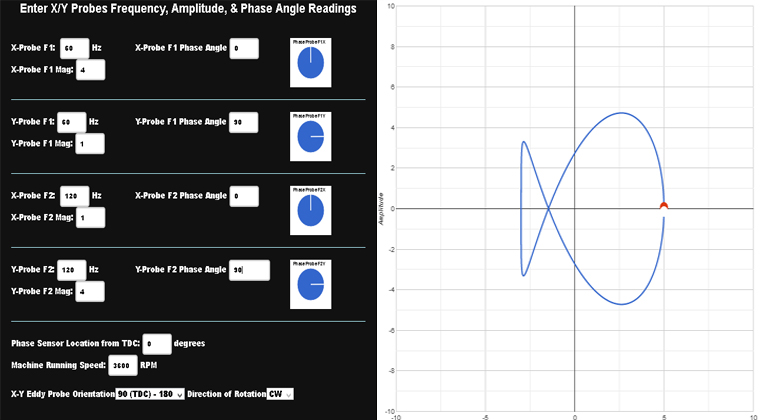

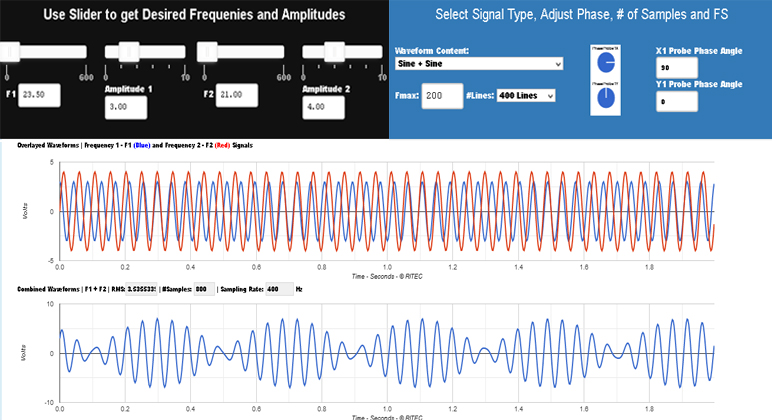

Generate Orbit Plots and experiment with changes to: Sub/Super-Syncrhonous Frequencies, Probe Orientations, Phase(s), Amplitude(s), and Machine Running Speed.

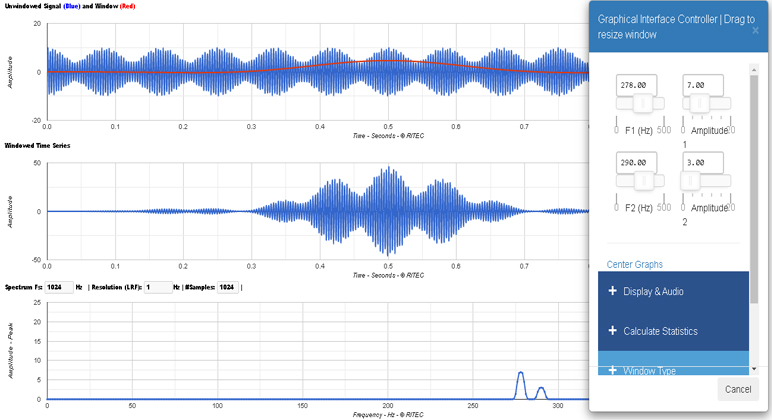

Demonstrates the Effects of Different Windows (e.g. Flat Top, Hamming, etc) on Amplitude and Frequency Resolution

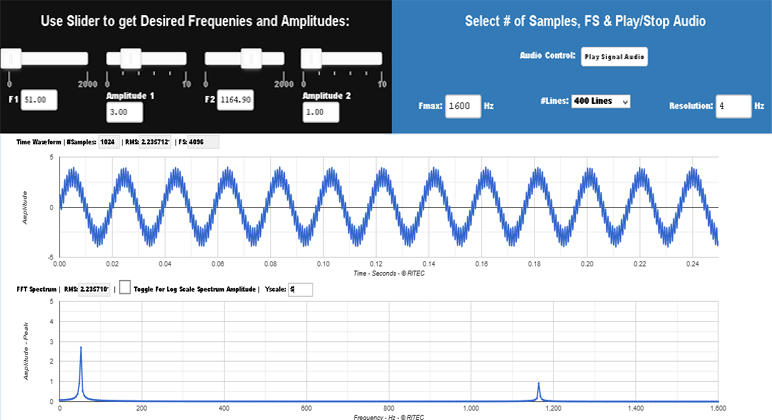

Generate Signals and play/hear the signal's sound. Change frequencies to generate higher/lower frequency signals, and generate a beating effect. All while observing the Time Waveform and Spectrum.

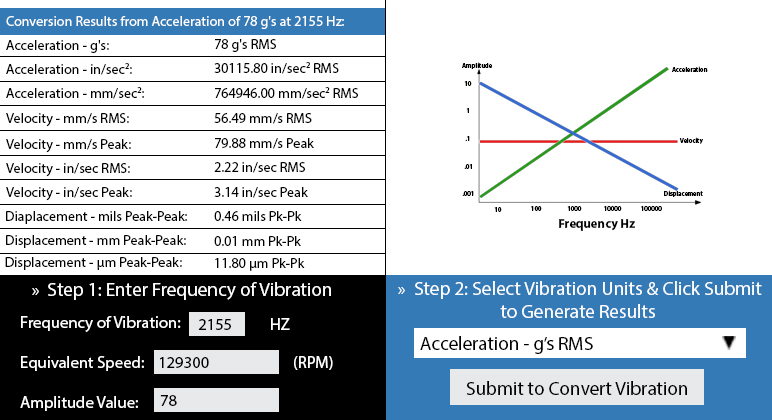

Convert Vibration Amplitudes of Single Frequency Sinusoidal Signals.

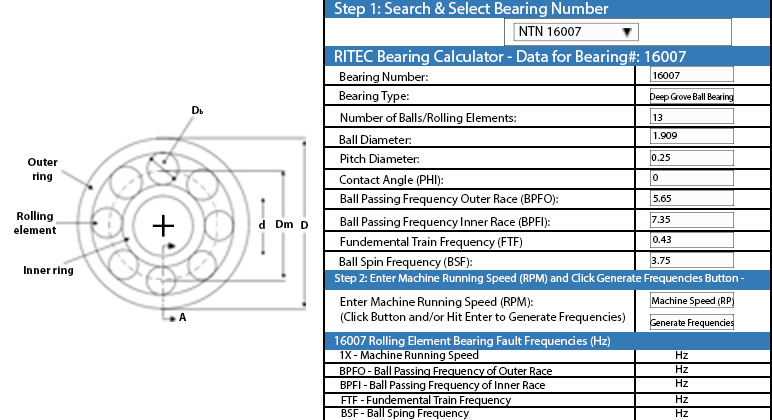

Calculate Fault Frequencies of more than 2,700 Bearing Types from: Cooper, Dodge, NTN, and SKF.

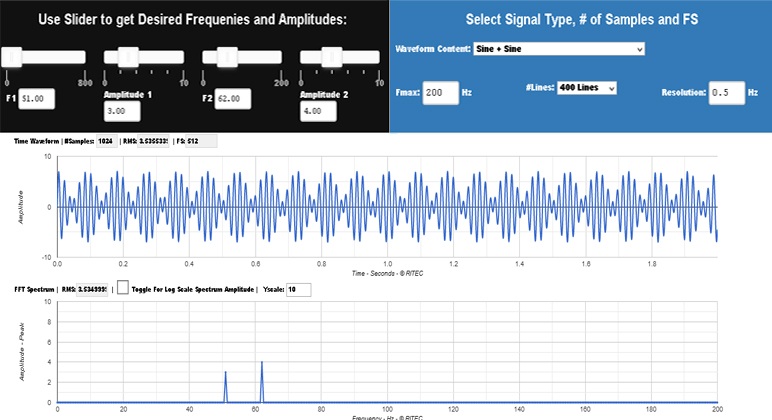

Generate Single or multiple frequency signals to view: Sinusoidal, Complex Periodic, Random, Square, and Modulated Signals. Adjust Fmax / #Lines to view effects of Aliasing and Resolution.

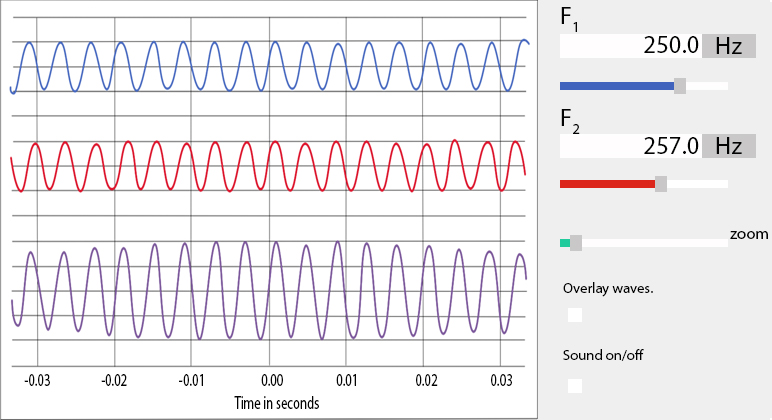

Simulate different types of time series types. Overlayed signals to view Beating.

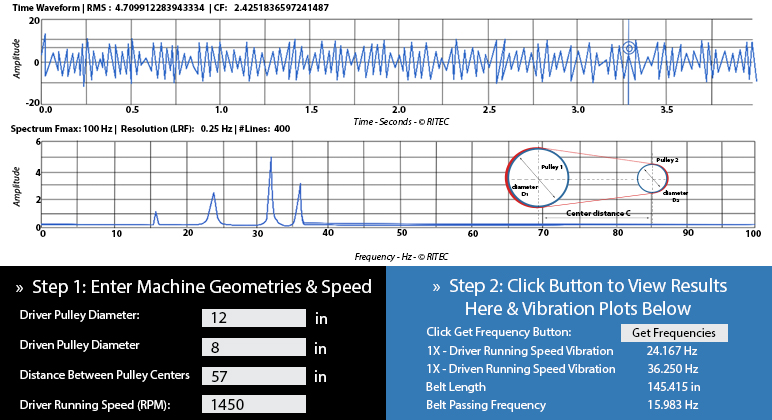

Calculate the Belt Passing Frequency of Vibration for Pulleys.

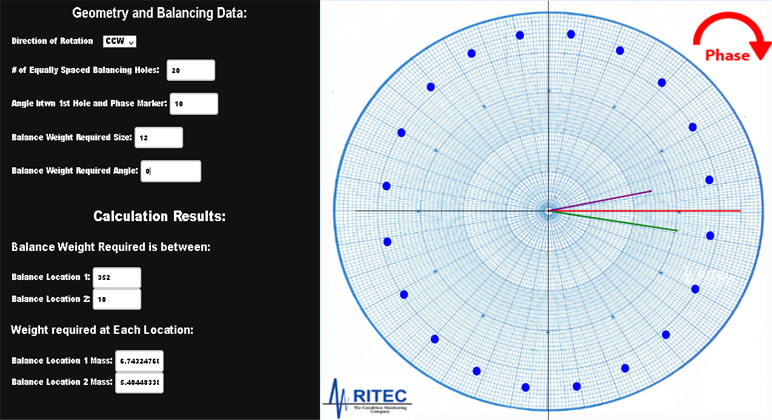

Calculate required weight splits for balancing in the case a balancing hole/location is unavailable.

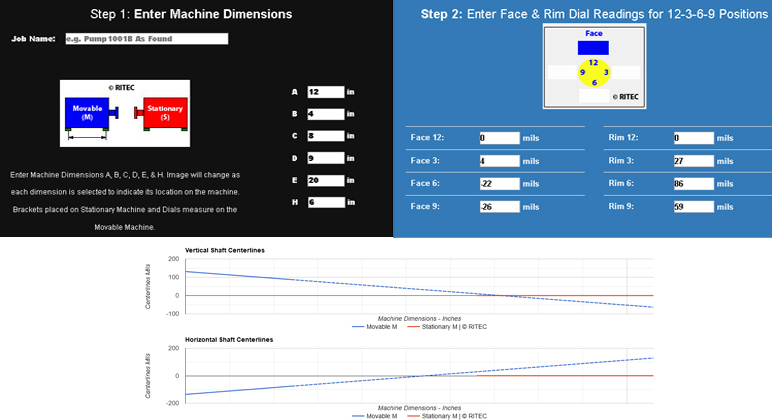

Calculate: Offset and Angular Alignment Parameters, Machine Feet Movements, Draw Shaft Centerlines, and generate an Alignment Report for Face & Rim Dial Guage Indicator Shaft Alignment Method.

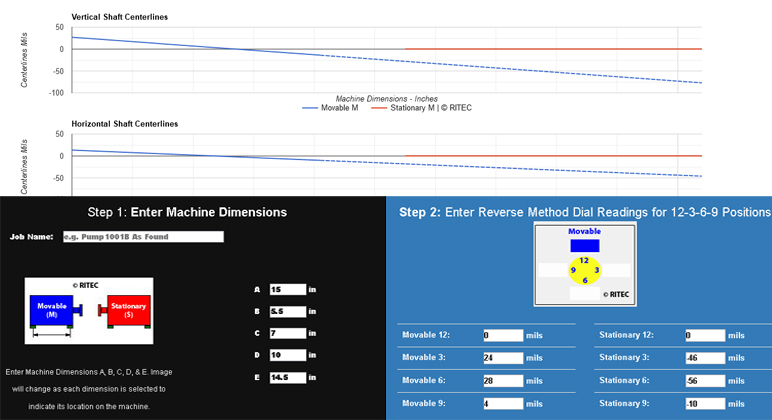

Calculate: Offset and Angular Alignment Parameters, Machine Feet Movements, Draw Shaft Centerlines, and generate an Alignment Report for Reverse Indicator Dial Guage Alignment Method.

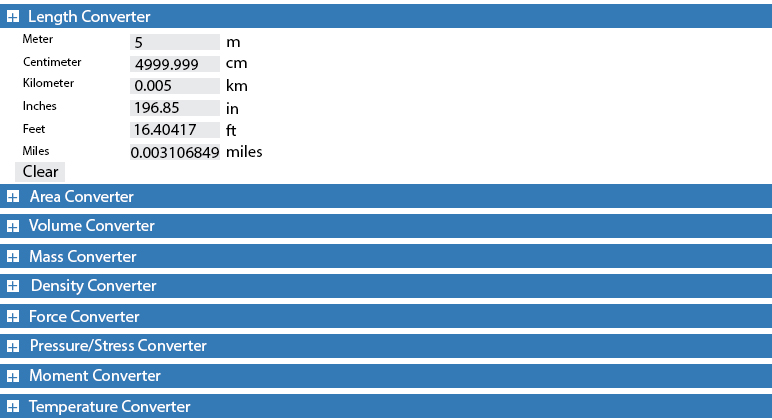

Converts: Length, Area, Volume, Mass, Density, Force, Pressure/Stress, Moment, Power, Speed & Temperature.

An interactive demo for the visualization of amplitude modulation effects on time-waveform signals.

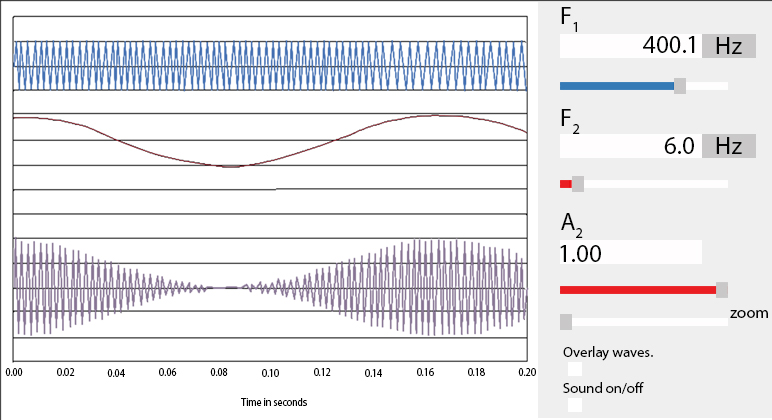

An interactive demo for the visualization of Beat Frequency phenomenon in signal time-wave form, due to the interaction of signals at or near the same frequency of vibration.

Abstract: Fans are probably the simplest types of rotating machinery. However, the diagnosis of Fan problems in the field may require the use of elaborate techniques for the proper diagnosis of fan malfunctions. These techniques range from the use of spectral analysis to the use of operating deflection shape analysis. This paper presents a diagnosis procedure and several case studies for the field diagnosis of fans from the cement, fertilizer, and petrochemical industries. These cases include resonance, rotor unbalance, gearbox wear, flexible supports, and bearing faults. The cases illustrate the use of particular diagnosis technologies to identify fan malfunctions.

Abstract: This paper presents cases of gearbox fault diagnosis in the field, and the methodology used in their diagnosis. The techniques used in the diagnosis include spectral analysis, time waveform analysis, envelope analysis, phase analysis, ODS analysis and resonance testing. The cases presented have a wide range including cases of misaligned gearboxes, casing distortion, backlash, wear, teeth overload and teeth resonance. The methods used in diagnosis and the corrective action are presented. These cases are from a wide range of industries including: cement, steel, and petrochemical industries.

Abstract: This case study describes the diagnosis of 4 similar large pumps that exhibited frequent shaft failures. The only symptom on vibration measurement on these pumps operating at about 3000 rpm, was the relatively high blade passing frequency at 300 Hz (6X). Many steps were taken to alleviate the problem. The machines were operated closer to the best efficiency point, a piping analysis was conducted to alleviate piping strain, and finally a complete dynamic analysis was conducted including resonance testing, operating deflection shape analysis (ODS) and rotordynamic analysis. The study revealed that the root cause of the problem was a very interesting resonant condition.

Abstract: A method of controlling the instability in fluid film bearings by using a magnetic bearing in combination with a fluid film bearing (whether it is a cylindrical journal bearing, an elliptic bearing, an offset-half bearing, a multi-lobe bearing, foil bearings or a tilting-pad bearing, does not really matter), wherein the fluid film bearing serves as the primary load carrying bearing and the magnetic bearing controls the instability of the fluid film bearing. This efficient combination results in bearings that can be used at high speeds without having neither stability nor reliability problems. An alternative method of controlling the instability in fluid film bearings is to disturb the flow in the axial direction, for example a sleeve journal bearing can be manufactured such that the bearing axis is skewed with the shaft axis or a variable geometery bearing can be manufactured to allow for bearing angular misalignment.

Abstract: A shaft rotating assembly typically used in gas turbine engines having a hybrid squeeze film damper for active control of rotors. The squeeze film damper includes seal ring means to confine the oil into a defined space. The seal ring means are axially movable preferably by controller means to provide long damper and short damper protection within the same defined space. The squeeze film damper thus can operate as a long damper near critical speeds and it can also operate as a short damper at operating speeds.

Abstract: In this paper, the application of neural networks and fuzzy logic to the diagnosis of faults in rotating machinery is investigated. The learning-vector-quantization (LVQ) neural network is applied in series and in parallel to a fuzzy inference engine, to diagnose 1x faults. The faults investigated are unbalance, misalignment, and structural looseness. The method is applied to a test rig (Hassan et al., 2003, ASME Paper No. GT 2003-38450), and the effectiveness of the integrated Neural Network and Fuzzy Logic method is illustrated.

The frequency response function of acceleration/force. Also known as inertance.

A device which is used to measure acceleration. A sensor or transducer (See Piezoelectric Accelerometer, Charge Mode Accelerometer, Triaxial Accelerometer) whose output is directly proportional to acceleration forces. The output is usually produced by force applied to a piezoelectric crystal which generates a current proportional to the applied force. This current is then amplified and displayed as a time waveform or processed by a Fourier transform to produce a frequency display. Single integration of the acceleration signal will produce a velocity display and double integration of the acceleration signal will produce a displacement display.

A change in the velocity of a body particle with respect to time. The parameter that an accelerometer measures (dv/dt). Usually given in terms of "g." (see g).

The maximum amplifier input signal amplitude under normal conditions before amplifier distortion occurs and becomes 1% nonlinear.

The detected energy that is generated when materials are deformed or break. For rolling element bearing analysis, it is the periodic energy generated by the over rolling of particles or flaws and detected by the display of the bearing flaw frequencies.

A specific procedure for solving mathematical problems. An FFT is an algorithm.

To digitize an analog signal for processing in digital instruments such as an FFT analyzer, it first must be periodically sampled, the sampling process occurring at a specific rate called the sampling frequency. As long as the sampling frequency is more than twice as high as the highest frequency in the signal, the sampled wave will be a proper representation of the analog waveform. If, however, the sampling frequency is less than twice as high as the highest frequency to be sampled, the sampled waveform will contain extraneous components called "aliases." The generation of aliases is called aliasing. An example of aliasing sometimes occurs in motion pictures, as for instance when the wagon wheels in a Western seem to be going backward. This is optical aliasing, caused by the fact that the frame rate of the movie camera (24 frames per second) is not fast enough to resolve the positions of the spokes. Another example of optical aliasing is the stroboscope, where a moving object is illuminated by a flashing light and can be made to appear stationary, or move backward. Aliasing must be avoided in digital signal analysis to prevent errors, and FFT analyzers always contain low pass filters in their input stages to eliminate frequency components higher than one-half the sampling frequency. These filters are automatically tuned to the proper values as the sampling frequency is changed, and this occurs when the frequency range of the analyzer is changed.

A condition whereby the axes of machine components are either coincident, parallel or perpendicular, according to design requirements, during operation.

The amount of mechanical gain of a structure when excited at a resonant frequency. The ratio of the amplitude of the steady state solution (amplitude at resonance) to the static deflection for the same force F. The amplification factor is a function of the system damping. For a damping ratio =0 (no damping) the amplification factor is infinite, for =1 (critically damped) there is no amplification.

Increase in signal due to the amplifier.

The measurement of energy or movement in a vibrating object. Amplitude is measured and expressed in three ways: Displacement (commonly in mils Pk-Pk); Velocity (commonly in In/Sec Pk); and Acceleration (commonly in gs RMS). Amplitude is also the y-axis of the vibration time waveform and spectrum, it helps define the severity of the vibration.

Quantities in two separate physical systems having consistently similar relationships to each other are called analogous. One is then called the analog of the other. The electrical output of a transducer is an analog of the vibration input of the transducer as long as the transducer is not operated in the nonlinear (overloaded) range. This is in contrast to a digital representation of the vibration signal, which is a sampled and quantisized signal consisting of a series of numbers, usually in binary notation.

The process of sampling an analog signal produces a series of numbers which is the digital representation of the same signal. The sampling frequency must be at least twice as high as the highest frequency present in the signal to prevent aliasing errors.

The angle between two shaft center lines; this angle is the same at any point along either centerline. It is normally specified in rise/run.

The low pass filter in the input circuitry of digital signal processing equipment such as FFT analyzers which eliminates all signal components higher in frequency than one-half the sampling frequency. See Aliasing.

To apodize is to remove or smooth a sharp discontinuity in a mathematical function, an electrical signal or a mechanical structure. An example would be to use a Hanning Window in the FFT analyzer to smooth the discontinuities at the beginning and end of the sample time record.

A rotor support system that does not provide uniform restraint in all radial directions. This is typical in industrial machinery where stiffness in one plane may be substantially different than stiffness in the perpendicular plane. Occurs in bearings by design, or from preloads such as gravity or misalignment.

Frequencies in a vibration spectrum that exceed shaft turning speed (TS), but are not integer or harmonic multiples of TS. Also commonly refered to as non-synchronous.

The angle between the steady state preload through the bearing centerline, and a line drawn between the bearing center and the shaft centerline. (Applies to fluid film bearings).

Auto correlation is a time-domain function that is a measure of how much a signal shape, or waveform, resembles a delayed version of itself. It is closely related to the Cepstrum, q.v. The numerical value of auto correlation can vary between zero and one. A periodic signal, such as a sine wave has an auto correlation that is equal to one at zero time delay, zero at a time delay of one-half the period of the wave, and one at a time delay of one period; in other words, it is a sinusoidal waveform itself. Random noise has an auto correlation of one at zero delay, but is essentially zero at all other delays. Auto correlation is sometimes used to extract periodic signals from noise. Certain dual-channel FFT analyzers are able to measure auto correlation.

In performing spectrum analysis, regardless of how it is done, some form of time averaging must be done to accurately determine the level of the signal at each frequency. In vibration analysis, the most important type of averaging employed is linear spectrum averaging, where a series of individual spectra are added together and the sum is divided by the number of spectra. Averaging is very important when performing spectrum analysis of any signal that changes with time, and this is usually the case with vibration signals of machinery. Linear averaging smoothes out the spectrum of the random noise in a spectrum making the discrete frequency components easier to see, but it does not actually reduce the noise level. Another type of averaging that is important in machinery monitoring is time domain averaging, or time synchronous averaging, and it requires a tachometer connected to the trigger input of the analyzer to synchronize each "snapshot" of the signal to the running speed of the machine. Time domain averaging is very useful in reducing the random noise components in a spectrum, or in reducing the effect of other interfering signals such as components from another nearby machine. See also Time Synchronous Averaging.

In the same direction as the shaft centerline.

Movement of one shaft along its centerline due to the freedom of movement permitted by a journal bearing or a sleeve bearing. This adjustment should be set before performing vertical or horizontal moves. The degree of axial float can be adjusted by the position of the stops, or whatever limits the motion.

A comparative calibration accomplished by mounting a test accelerometer to a reference accelerometer such that both are subjected to identical motion.

A condition where a rotor can rotate freely for a certain angular distance before encountering any resisting force. It may be measured in degrees. This term normally applies to couplings and gears.

Balance-of-Plant (BoP) is a term given to all the infrastructural components. For example, it can refer to the supporting equipment and auxiliary components that are required to make a power plant or energy system operate.

The frequency range over which a filter passes a signal within 3 dB of full strength. Outside the filter bandwidth, the signal is attenuated. The further outside, the greater the attenuation.

The difference in frequency between the upper and lower cutoff frequencies of a bandpass filter or other device is called the bandwidth of the filter or device.

Accelerometer base that is electrically insulated from its case, output signal, and the test structure it is mounted to.

The surface to which the feet of a machine are attached.

The parameter that quantifies the unwanted output signal picked up by a motion transducer when its mounting surface is subjected to mechanical strains.

Primarily two types, rolling element and sleeve or plain bearing. Rolling element bearings consist of four parts: an inner race, an outer race, balls or rollers, and a cage to maintain the proper separarion of the rolling elements. A sleeve bearing is a cylinder of alloy metal surrounding the rotating shaft. Contact between the shaft and sleeve is prevented by a lubrication film.

Faults in any of the four bearing components will generate specific frequencies dependent upon the bearing geometry and rotating speed. BPFO - Ball Pass Frequency, Outer Race BPFI - Ball Pass Frequency, Inner Race BSF - Ball Spin Frequency FTF - Fundamental Train Frequency.

A misalignment that results when the bearings supporting a shaft are not aligned with each other. The bearings may not be mounted in parallel planes, cocked relative to the shaft, or distorted due to foundation settling or thermal growth.

Each bearing manufacturer has specific codes applied as prefixes and suffixes to their bearings. These codes inform the user of the construction, materials, clearances, and other factors used in the construction of the bearing. Consult the individual manufacturer's handbook for specific code meaning.

If two vibration components are quite close together in frequency and if they are present at the same time at the same place, they will combine in such a way that their sum will vary in level up and down at a rate equal to the difference in frequency between the two components. This phenomenon is known as beating, and its frequency is the beat frequency. There is confusion in some areas between beating and amplitude modulation, which also can produce an undulating vibration level. Amplitude modulation is different from beating, and is caused by a high-frequency component being multiplied by a lower-frequency component and is thus a nonlinear effect, whereas beating is simply a linear addition of two components whose frequencies are close to one another.

An accelerometer design that stresses the piezoelectric element by bending it. This design is primarily used in low frequency, high sensitivity applications.

See Blocking Capacitor.

abr. (BOV). syns. Bias Voltage, Rest Voltage. The DC voltage at the output of an amplifier on which the AC dynamic signal is superimposed.

In an FFT spectrum, the individual frequencies at which the amplitudes are calculated, commonly called "lines."

Effective Binwidth *these terms need more work* The binwidth equals the frequency span divided by the number of lines. Effective binwidth equals the binwidth times the window noise factor.

Short for binary digit. A number expressed in binary notation utilizes the digits 1 and 0, and these are called bits. Any number can be expressed with combinations of them.

A capacitor placed in series with the input of a signal conditioning or measurement device that blocks the DC Bias Voltage but passes the AC signal.

The situation whereby a machine cannot be moved in the desired direction because of mounting hole restrictions.

A shaft condition such that the geometric centerline of the shaft is not straight.

The total noise of an electronic circuit within a specified frequency bandwidth. The total noise of the electronic circuit is usually expressed in rms volts.

The total vibration amplitude within a specified frequency bandwidth.

A memory location in a computer or digital instrument which is set aside for temporarily storing digital information while it is waiting to be processed.

A single channel approximation to a two channel impact test. This method works because the impacting force approximates an impulse and imparts broadband excitation over a limited frequency range. Since the Fourier Transform of the impulse response function is the frequency response function, it provides a good method of estimating the natural frequencies of the structure.

Term used to describe the spectral overall RMS level multiplied by sqrt (2). Sometimes referred to as "derived peak" or "pseudo peak."

Is the ability of a body to store an electrical charge. A material with a large capacitance holds more electric charge at a given voltage, than one with low capacitance. Any object that can be electrically charged exhibits capacitance, however the concept is particularly important for understanding the operations of the capacitor, one of the three fundamental electronic components (along with resistors and inductors).

Sensor case that is electrically insulated from the output signal and test structure.

The cepstrum is the forward Fourier transform of a spectrum. It is thus the spectrum of a spectrum, and has certain properties that make it useful in many types of signal analysis. One of its more powerful attributes is the fact that any periodicities, or repeated patterns, in a spectrum will be sensed as one or two specific components in the cepstrum. If a spectrum contains several sets of sidebands or harmonic series, they can be confusing because of overlap. But in the cepstrum, they will be separated in a way similar to the way the spectrum separates repetitive time patterns in the waveform. Gearboxes and rolling element bearing vibrations lend themselves especially well to cepstrum analysis. The cepstrum is closely related to the auto correlation function.

The mathematical equation whose solution defines the dynamic characteristics of the structure in terms of its natural frequencies, damping, and mode shapes. The mathematical formulation of the characteristic equation is called the Eigenvalue problem. The characteristic equation is obtained from the equations of motion for the structure.

An amplifier that compensates its gain such that it conditions a charge signal independently of any capacitance parallel to the source of the charge signal: i.e. cable capacitance. A charge to voltage converter. A capacitive feedback amplifier which converts the high impedance output from a charge mode sensor to a low impedance voltage signal.

Converts the high impedance output of a charge mode sensors to a low impedance voltage signal.

A piezoelectric accelerometer that does not contain an internal amplifier and produces a high impedance charge signal.

The amount of charge produced by a charge mode accelerometer per unit of acceleration and is expressed as picocoulomb/g (pC/g) or pC/ms2 (see picocoulomb and g2).

A single-degree of freedom curve fitting routine that tries to fit a mode to a circle (Nyquist plot of a single-degree of freedom system). The modal coefficient is determined by the diameter of the circle and the phase by its location relative to the imaginary axis. For a real mode, it should be either completely above or completely below the imaginary axis.

Output limitation when a signal amplitude exceeds the limits imposed by the amplifier and the supply voltage.

The constant value or factor of expansion of a material for a given increase in temperature, divided by the length of the material. This is different for each material.

Coherence is a number between one and zero, and is a measure of the degree of linearity between two related signals, such as the input force of a structure related to the vibration response to that force. Coherence is thus a two-channel measurement, and does not apply to single-channel measurements of vibration signatures. In a frequency response measurement of a mechanical structure, if the structure is linear, the coherence will be one, but if there is some nonlinearity in the structure or if there is noise in a measurement channel, the coherence will be less than one. The dual-channel FFT analyzer is able to measure the coherence between the two channels, and it is a useful tool in determining good from noisy or meaningless data.

Coherence is a function of frequency that measures amount of power in the response (output) that is caused by the power in the excitation (input). If it is 100% coherent, the value is 1.

Another name for the real part of the frequency response function.

Machine condition in which alignment procedures are normally performed. Changes in off-line to on-line running conditions should be allowed for during this procedure so that the machine can "grow" into alignment during operation. Also known as static alignment or primary alignment.

The points on a structure have varying phase relationships between them at a natural frequency. This is unlike a real mode where the phase between points is either 0° or 180°.

Frequency response function of displacement/force. Also known as Dynamic Compliance.

An accelerometer design that stresses the piezoelectric element in the compressive direction: i.e. the electrode faces move toward and away from each other.

The process of monitoring machinery condition through various parameters and tests(usually vibration) in order to identify if a significant change, which is indicative of a developing fault has occured. It is a major component of predictive maintenance. Condition monitoring allows maintenance to be scheduled, or other actions to be taken to prevent failure and avoid its consequences. Condition monitoring has a unique benefit in that conditions that would shorten the normal lifespan can be addressed prior to development into a major failure. Condition monitoring techniques are normally used on rotating equipment and other machinery (pumps, motors, engines, presses, compressors).

Nonlinear damping that is a result of rubbing, looseness, etc.

Mechanical fixture for joining two shafts.

The smallest amount of damping required to return a system to its equilibrium condition without oscillating.

Cross correlation is a measure of the similarity in two time domain signals. If the signals are identical, the cross correlation will be one, and if they are completely dissimilar, the cross correlation will be zero. Certain dual-channel FFT analyzers are able to measure cross correlation.

A semiconductor device that limits and regulates electrical current independent of voltage.

The damped natural frequency is the frequency at which a damped system will oscillate in a free vibration situation. for a single-degree-of-freedom system.

Energy dissipation in an oscillating structure. For free vibration, that results in a decay in the amplitude of motion over time.

The ratio of actual damping in a system to its critical damping ( = C / C c )

The number of coordinates or independent variables it takes to completely describe the location of a structure.

An electronic circuit that determines the amplitude level of a signal in accordance with certain rules. The simplest type of detector consists of a resistor and a capacitor, and it measures the average value of a fluctuating DC signal. A more complex but much more useful type of detector is an RMS detector. RMS detectors are used because they are proportional to the power or energy present in the signal or a vibration.

A type of signal whose spectrum consists of a collection of discrete components, as opposed to a random signal, whose spectrum is spread out or "smeared" in frequency. Some deterministic signals are periodic, and their spectra consist of harmonic series. Vibration signatures of machines are in general deterministic, containing one or more harmonic series, but they always have non- deterministic components, such as background noise.

Instrument used to measure amounts of motion, or displacement in thousandths of an inch (mils) increments.

In vibration analysis, differentiation is a mathematical operation that converts a displacement signature to a velocity signature, or a velocity signature to an acceleration signature. It is performed electronically on an analog signal or can be performed digitally on a spectrum. Differentiation is an inherently noisy operation, if performed on an analog signal, adding a significant amount of high frequency noise to the signal, and is generally not used very much in machinery vibration analysis. It is not inherently noisy if it is done digitally on the FFT spectrum. See also Integration, which is the inverse of differentiation.

Digital instrumentation consists of devices that convert analog signals into a series of numbers through a sampling process and an analog to digital converter. They then perform operations on the numbers to achieve such effects as equalization, data storage, data compression, frequency analysis, etc. This process in general is called digital signal processing. It is characterized by several advantages and disadvantages. One advantage is that the converted signals can be manipulated, transformed and copied without introducing any added noise or distortion. The disadvantage is that the signal representation may not be truly representative of the original signal.

The time required for a sensor or measuring system to discharge its signal to 37% of the original value from a step change in measurement. This time constant directly relates to the low frequency measuring capability for both transient and sinuoidal events. (It should not be confused with rise time which relates to high frequency responses.)

With reference to a spectrum, discrete means consisting of separate distinct points, rather than continuous. An example of a discrete spectrum is a harmonic series. An FFT spectrum, which consists of information only at specific frequencies (the FFT lines), is actually discrete regardless of the input signal. For instance, the true spectrum of a transient is continuous, and the FFT of a transient appears continuous on the screen, but still only contains information at the frequencies of the FFT lines. The input signal to an FFT analyzer is continuous, but the sampling process necessary to implement the FFT algorithm converts it into a discrete form, with information only at the specific sampled times.

The mathematical calculation that converts, or "transforms" a sampled and digitized waveform into a sampled spectrum. The fast Fourier transform, or FFT, is an algorithm that allows a computer to calculate the discrete Fourier transform very quickly. See also Fast Fourier Transform.

Symbol: x. The measured traveled distance by a point from its position at rest. Peak to peak displacement is the total measured movement of a vibrating point between its positive and negative extremes. Measurement units usually expressed in microns or mils for mechanical machinery vibration.

A sensor whose output varies proportionally to the displacement aspect of motion.

A secondary alignment method. Consists of two bars that are similar in configuration to reverse dial indicator bars. However these bars are not mounted on the shaft, they are mounted to the machine. Each bar is fitted with a proximity probe and it corresponds to a block on the other bar. As the machines move to their on-line condition the gap between the proximity probe and the metal block changes, which changes the voltage. The analyzer converts the voltage to a distance and from these distances, the alignment corrections can be calculated.

A domain is a set of coordinates in which a mathematical function resides. A waveform, for instance, has dimensions of amplitude and time, and it is said to exist in the time domain, while a spectrum has dimensions of amplitude and frequency, and is said to exist in the frequency domain.

Permanently mounted pins in the baseplate, which are inserted into close tolerance holes in the machine's feet, used to bring machines back to the same aligned position.

A frequency response measurement where the excitation point and direction are the same as the response point and direction.

See compliance.

The ratio in dB between the highest signal level that can be tolerated without distortion and the broadband noise level measured in the absence of the signal.

The frequency response function of force/displacement.

A condition in which an electromagnetic field produces an unwanted signal.

The variation of the outer diameter of a shaft surface when referenced to the true geometric centerline of the shaft. Out-of- roundness. See also Runout.

The vector difference between the bearing centerline and the average steady-state journal centerline. Applies to sleeve bearings not anti-friction bearings.

A non-contact electrical device that measures the displacement of one surface relative to the tip of the probe. Construction consists of an electrical coil of various lengths and diameters. This coil located in the tip of the probe is energized producing an electrical field around the tip of the probe. When a conductive surface is placed in the field and the distance from the probe is noted, variations in this gap can be determined by the variations in the voltage flow to the probe tip.

The frequency response function of force/acceleration.

The roots of the characteristic equation.

The mathematical formulation and solution of the characteristic equation is called the Eigenvalue problem.

The mode shape vectors.

Noise, or interference, can be defined as undesirable electrical signals, which distorts or interferes with an original (or desired) signal. Noise could be transient (temporary) or constant. Constant noise can be due to the predictable 50 or 60 Hz AC 'hum' from power circuits or harmonic multiples of power frequency close to the data communications cable. Noise can be internal, generated from within the system or from an outside source (external). Typical sources of noise are devices, which produce quick changes (spikes) in voltage or current or harmonics, such as large electrical motors being switched on, fluorescent lighting tubes, solid-state converters or drive systems, lightning strikes, high-voltage surges due to electrical faults, welding equipment.

Is the resultant output that is generated when an accelerometer is subjected to external AC magnetic fields. This output is considered noise and therefore contributes to measurement errors. A significant effort is made to avoid the use of magnetic material during the accelerometer product design phase in order to minimize the risk of electromagnetic sensitivity. Despite this, most accelerometers still exhibit some degree of electromagnetic sensitivity.

See axial float.

The units in which a measurement is made; for instance velocity may be expressed in millimeters per second, miles per hour, or furlongs per fortnight, depending on the use to which the data will be put. Modern instrumentation, such as FFT analyzers allow one to specify what the engineering units are and to apply conversion factors if needed.

A seconardy alignment method used to measure the difference between on-line and off-line running conditions. The method measures the change in distance and a change in angle between two tooling balls. One ball is fixed to the bearing and the other ball is fixed to a fixed reference point (usually the floor). The balls are connected by means of an inside micrometer with a resolution of at least 0.001." This should be set up for both sides of the bearing, so the readings can be taken simultaneously. And readings should be taken at every bearing. As the machine "grows" the distances betwen the balls and the angle between the inside micrometer and a fixed location (also usually the floor) will change. And these changes can be used to determine the changes in alignment.

A special windowing function for minimizing leakage in lightly damped structures that is used in impact testing. In a lightly damped structure, oscillations may not die out within the sampled time data block, T, which results in leakage error. An exponential window adds damping to the time signal to force it to die out within the time T, thus minimizing leakage. The added damping is then removed mathematically after the signal is processed.

A method of shaft alignment where the indicators are mounted both radially and axially on one machine or the other, not both.

The FFT is an algorithm, or digital calculation routine, that efficiently calculates the discrete Fourier transform from the sampled time waveform. In other words it converts, or "transforms" a signal from the time domain into the frequency domain. See also DFT. The illustration shows the relation between the time record length, the time between samples, the frequency span f and the frequency resolution. The most important relation here is that the frequency resolution is inversely proportional to time record length. Therefore, high-resolution spectrum analysis of necessity takes a long time to collect the time record.

The FFT analyzer is a device that uses the FFT algorithm to calculate a spectrum from a time domain signal, and is the most common type of spectrum analyzer available today. The FFT analyzer is a very useful device, and is available in a great variety of models with varying complexity. It is the heart of any machinery predictive maintenance program. See also Fast Fourier Transform.

A filter is an electrical circuit that allows signals in certain frequency ranges to pass through, and attenuates or blocks all other frequencies. There are many types of filters, such as low pass filters, high pass filters, and band pass filters. Examples of filters used in machinery monitoring instruments are low pass filters to reject high frequency noise and to prevent aliasing, and high pass filters to reject low frequency noise. Variable frequency band pass filters were used in the past to perform spectrum analysis, but they have been largely supplanted by the FFT analyzer.

A computer-aided design technique for mathematically modeling a structure. Finite element modeling is used for structural analysis, heat transfer analysis, and modal analysis.

The machine whose position is not changed during shaft alignment. Compare with Shim Machine.

The frequency range of an accelerometer where the ratio of the electrical output to the vibration input deviates by no more than ±5% (linear range), referenced at 100 Hz.

The flattop window is a special window used in some FFT analyzers in addition to the more common Hanning window and rectangular window. The flattop window does not allow as fine a frequency resolution as the Hanning window, but it will accurately measure the amplitude level of a signal at any frequency, even if the frequency is between the lines of the FFT analysis. It is used in transducer calibration systems to increase amplitude accuracy.

Structured with a crystal sensing element which is stressed in a bending mode due to vibratory motion.

A special windowing function for minimizing noise in impact testing. Since the duration of the actual impact is usually very short relative to the overall digitized time sample, the frequency response function of the force signal can have a low signal to noise ratio. The force window does not alter the actual force pulse but minimizes the noise in the rest of the data block giving a much improved signal to noise ratio.

Mathematically calculating the system response to an arbitrary forcing function using modal analysis data as the system model.

The oscillation of a system under the action of a forcing function.

The surface to which the machine baseplate is mounted.

The famous many-talented French engineer, mathematician, and one time president of Egypt, who devised the Fourier series and Fourier Transform for the conversion of time functions into frequency functions and vice versa.

The mathematically rigorous operation which transforms from the time domain to the frequency domain and vice versa. See also Fast Fourier Transform.

Fourier analysis is another term for spectrum analysis, although it generally refers to analysis using an FFT analyzer, q.v.

The repetition rate of a periodic vibration, per unit of time, determined by taking the reciprocal of the period (T). Frequency is expressed in three ways: Hz (how many cycles per second); cpm (how many cycles per minute); and orders (how many cycles per shaft turning speed [TS]). Frequency is also the x-axis of the vibration spectrum; it identifies the source of the vibration.

Frequency is the reciprocal of time. If an event is periodic in time, i.e. if it repeats at a fixed time interval, then its frequency is one divided by the time interval. If a vibrating element takes one tenth of a second to complete one cycle and return to its starting point, then its frequency is defined to be 10 cycles per second, or 10 hertz (Hz). Although the SI standard unit of frequency is the Hz, when analyzing machinery vibration it is sometimes more convenient to express frequency in cycles per minute (cpm), which corresponds to rpm. Frequency in cpm is simply frequency in Hz times 60. Another common frequency representation used in machinery monitoring is multiples of turning speed, or "orders." Frequency in orders is frequency in cpm divided by the turning speed of the machine. The second order is then the second harmonic of turning speed, etc. This is especially convenient if the machine is varying in speed, for the frequency representation on a spectrum will be the same regardless of speed. Two spectra from the same machine can therefore more easily be compared if they are both expressed in orders. Conversion of the frequency axis of a spectrum to orders is called "order normalization," and is done by vibration monitoring analyzers.

Vibration exists in time, and it is said to be in the "time domain." The representation of a vibration signal in the time domain is a "wave form," and this is what one would see if the signal were displayed on an oscilloscope. If the waveform is subjected to a spectrum analysis, the result is a plot of frequency vs amplitude, called a spectrum, and the spectrum is in the frequency domain. The waveform is said to be transformed from the time domain to the frequency domain. Most detailed analysis of machinery vibration data is done in the frequency domain, but certain information is more easily interpreted in the time domain.

The frequency response function, also called the FRF, is a characteristic of a system which has a measured response resulting from a known applied input. In the case of a mechanical structure, the frequency response is the spectrum of the vibration of the structure divided by the spectrum of the input force to the system. To measure the frequency response of a mechanical system, one must measure the spectra of both the input force to the system and the vibration response, and this is most easily done with a dual-channel FFT analyzer. Frequency response measurements are used extensively in modal analysis of mechanical systems. The frequency response function is actually a three-dimensional quantity, consisting of amplitude vs. phase vs. frequency. Therefore a true plot of it requires three dimensions, and this is difficult to represent on paper. One way to do it is the so-called Bode plot, which consists of two curves, one of amplitude vs. frequency and one of phase vs. frequency. Another way to look at the frequency response function is to resolve the phase portion into two orthogonal components, one in-phase part (called the real part), and one part 90 degrees out of phase (called the "quadrature" or "imaginary" part). Sometimes these two phase parts are plotted against each other, and the result is the so-called Nyquist plot.

The output to input relationship of a structure. Mathematically, it is the Fourier transform of the output divided by the Fourier transform of the input. It is also the transfer function measured along the j axis in the s-plane.

For an N degree of freedom system, it is an N x N symmetrical matrix whose elements are the frequency response functions between the various points on the structure. Rows correspond to response points and columns to excitation points. For example, H23 is the frequency response with excitation at point 3 and response at point 2. The matrix is redundant, that is, by knowing any row or column, the other elements of the matrix can be computed.

The rotation frequency or rate of the cage supporting the rolling elements in an anti-friction bearing. The FTF is always less than one-half shaft TS.

Data taken in the time domain and converted to the frequency domain by applying the Fast Fourier Transform (FFT).

A measure of the change in a quantity, usually sensitivity or machinery vibration response, as a function of frequency.

Standard unit of acceleration equal to one earth’s gravity at mean sea level – one “g” equals 386.1 in/sec2 or 9.807 m/s2.

Refers to a condition when the amplifier ground is electrically isolated from the test structure ground. See base isolation and case isolation.

A condition where a sensor signal return lead or cable shield is grounded at both sensor as well as remote readout and where the grounds are of differing electrical potential. Such conditions cause ” Ground Loop Noise” at frequencies between 50 and 60 Hz as well as multiples.

Named after its originator, the Hamming window is a Hanning window sitting on top of a small rectangular pedestal. Its function is similar, but has its first sidelobes 42 dB down, whereas the Hanning window's first sidelobes are only 32 dB down. Thus the Hamming has better selectivity for large signals, but it suffers from the disadvantage that the rest of the sidelobes are higher, and in fact fall off slowly at 20 dB per octave like those of the rectangular window. The Hamming window had some advantage in the days when FFT analyzers only had 50 dB or so of dynamic range, but nowadays it is essentially obsolete.

The Hanning window, also called "Hanning weighting," is a digital manipulation of the sampled signal in an FFT analyzer which forces the beginning and ending samples of the time record to zero amplitude. This compensates for an inherent error in the FFT algorithm which would cause the energy at specific frequencies to be spread out rather than well defined in frequency. The Hanning window causes a distortion of the wave form used by the analyzer to calculate the spectrum, and this results in the measured levels being too low. When processing continuous data, this effect is compensated for, but an error is introduced if the Hanning window is used for transient data.

A frequency that is an integer multiple of a given (subsynchronous, synchronous or nonsynchronous) frequency.

Harmonics, also called a harmonic series, are components of a spectrum which are integral multiples of the fundamental frequency. A harmonic series in a spectrum is the result of a periodic signal in the waveform. Harmonic series are very common in spectra of machinery vibration.

The unit of frequency in the SI measurement system is the hertz, abbreviated Hz. One hertz is equal to one cycle per second. The name is in honor of Heinrich Hertz, an early German investigator of radio wave transmission.

A filter that passes signal frequencies above a specific, or cut off, frequency is called a high pass filter. They are used in instrumentation to eliminate low-frequency noise, and to separate alternating components from direct (DC) components in a signal.

Usually relates to a high value of resistance such as at the input to an amplifier or output of a charge mode piezoelectric sensor.

Non-uniqueness in the relationship between two variables as a parameter increases or decreases. Also called deadband, or the portion of the system's response where a change in input does not produce a change in output.

Energy losses within a structure that are caused by internal friction within the structure. These losses are independent of speed or frequency of oscillation but are proportional to the vibration amplitude squared.

A plot of the imaginary part of the frequency response function versus frequency. For a single-degree-of-freedom system, the magnitude is a maximum or minimum at the damped natural frequency.

A method of measuring the frequency response function of a structure by hitting it with a calibrated hammer and measuring the system's response. The impact hammer is instumented with a load cell to measure the input force pulse while the response is typically measured using an accelerometer. The impact imparts a force pulse to the structure which excites it over a broad frequency range.

The mechanical impedance of a point on a structure is the ratio of the force applied to the point to the resulting velocity at the point. It is a measure of how much a structure resists motion when subjected to a given force, and it is the reciprocal of mobility. The mechanical impedance of a structure varies in a complicated way as frequency is varied. At resonance frequencies, the impedance will be low, meaning very little force can be applied at those frequencies. Mechanical impedance measurements of machine foundations are sometimes made to insure their suitability for the machine in question. For instance, it would not be good to have a foundation resonance near the turning speed of the machine.

The response of a system to a unit impulse or Dirac's delta function. The Fourier transform of the impulse response is the frequency response function.

A gravity device that measures angular position in degrees.

A type of soft foot that is caused by external forces (coupling, pipe strain, etc.) acting on a machine independent of the foot to baseplate connection.

The frequency response function of acceleration/force. Also known as accelerance.

Integration is the mathematical operation which is the inverse of differentiation. In vibration analysis, integration will convert an acceleration signal into a velocity signal, or a velocity signal into a displacement signal. Integration can be done with excellent accuracy with an analog integrator in the time domain or can be done digitally in the frequency domain. For this reason an accelerometer is the transducer of choice because velocity and displacement can be so easily derived from its output. An analog integrator is actually a low pass filter with 6 dB of attenuation per octave. This is true of an analog integrator only above its low cutoff. And since the low cutoff cannot be zero, analog integrators have low-frequency limits, usually either 1 or 10 Hz.

A bolt or screw attached to the baseplate or foundation that is used to move or position the machine that is being moved.

A long shaft that is used as a spacer between two machines. Also, a long turning shaft with several sheaves.

The physical location of a rotor relative to the fixed, or non- rotating parts of the machine.

In an FFT analyzer, the input signal is recorded in time blocks, called time records, and individual spectra are computed from each block of data. Because the input signal period is not synchronized with the duration of the time block, the signal will be truncated at the beginning and end of the block. This truncation causes an error in the calculation which effectively spreads out, or "smears" the spectrum in the frequency domain. This phenomenon is called leakage; the signal energy essentially "leaks" from a single FFT line to adjacent lines. Leakage reduces the accuracy of the measured levels of peaks in the spectrum, and reduces the effective frequency resolution of the analysis. Leakage is worst for continuous signals and rectangular window, and it is greatly reduced by use of the Hanning window, which forces the signal level to zero at the ends of the data block. See also Hanning.

In common usage the level of a signal is its amplitude, but strictly speaking the term should be reserved for the amplitude expressed on a decibel scale relative to a reference value.

The closeness of a calibration curve to a specified straight line. Linearity is commonly specified as a % of full scale based on best straight line through zero.

In an FFT spectrum, the frequency difference between two adjacent bin centers or lines.

A line spectrum is a spectrum where the energy is concentrated at specific frequencies (lines or bins), as opposed to a continuous spectrum where the energy is smeared out over a band of frequencies. A deterministic signal will have a line spectrum, and a random signal will have a continuous spectrum. Spectra generated by machine vibration signatures are always a combination of these two types.

Usually relates to a low value of resistance such as the output of an amplifier of the sensor.

A filter (mechanical or electrical) which attenuates high frequencies and passes low frequencies. The filter passes signals with less than 3 dB attenuation up to its cutoff frequency, and attenuates the signal above that frequency. The attenuation slope is called the roll off, q.v. An anti-aliasing filter is an example of a low pass filter.

Three or more machines that must be aligned to one another.

The frequency response function of force/velocity.

This is one thousanth of a radian. A radian is an angle whose subtended arc is equal to the radius at which the arc is measured. It amounts to about 57.3 degrees. There are 2 radians in a circle. A unit (normally metric) used to describe the angle of one machine centerline to the other. It is the equivalent to 1 mils/inch. It can also be expressed as rise/run. (1 unit = 17.45 milliradians).

A unit of measure for displacement (thousandths of an inch). Usually measured in mils peak to peak, which represents total displacement.

A unit (normally English) used to describe the angle of one shaft centerline to the other. It is equivalent to milliradians. It can also be expressed as rise/run (1 unit = 17.45 mils/inch), as long as the rise is measured in mils and the run is measured in inches.

The frequency response function of velocity/force. Mobility is the inverse of mechanical impedance. It is a measure of the ease with which a structure is able to move in response to an applied force, and varies it with frequency. The vibration measured at a point on a machine is the result of a vibratory force acting somewhere in the machine. The magnitude of the vibration is equal to the magnitude of the force times the mobility of the structure. From this it follows that the amplitude of the destructive forces acting on a machine are not determined directly by measuring its vibration if the mobility of the machine is not known. For this reason, it is a good idea to measure the mobility at the bearings of a machine in order to find out the levels of the forces acting on the bearings due to imbalance or misalignment.

The process of determining a set of generalized coordinates for a system such that the equations of motion are both inertially and elastically uncoupled. More commonly, it is a process of determining the natural frequencies, damping factors, and mode shapes for a structure. This is usually done either experimentally through frequency response testing or mathematically using finite element analysis.

The relative position of all points on a structure at a given natural frequency.

A threaded screw used to rigidly attach a motion sensor to the structure under test.

The optimum torque applied to the sensor when mounting with a threaded stud.

An N-degree-of-freedom system is a system whose position in space can be completely described by N coordinates or independent variables.

Unit of acceleration in meters/second/second.

The frequency of oscillation of the free vibration of a system if no damping were present. For a single-degree-of-freedom system, the natural frequency where k is the spring constant and m is the mass.

A point or line on a vibrating structure that remains stationary.

National Institute of Standards and Technology (formerly NBS National Bureau of Standards) is a national standards lab which provides calibration certification for primary reference standards.

Any signal other than the true signal from the measurand. Can be random or periodic.

Frequencies in a vibration spectrum that exceed shaft turning speed (TS), but are not integer or harmonic multiples of TS. See asynchronous.

Refers to standardization of an accelerometer output to a specified value and tolerance, e.g 100 mV/g ñ2%.

Digital signal processing requires analog to digital (A to D) conversion of the input signal. The first step in A to D conversion is sampling of the instantaneous amplitudes of signal at specific times determined by the sampling rate. If the signal contains any information at frequencies above one-half the sampling frequency, the signal will not be sampled correctly, and the sampled version of the signal will contain spurious components. This is called aliasing. The theoretical maximum frequency that can be correctly sampled is equal to one-half the sampling rate, and is called the Nyquist frequency. In all digital signal processing systems, including FFT analyzers, the sampling rate is made to be significantly greater than twice the highest frequency present in the signal in order to be certain the aliasing will not occur.

An octave is a frequency interval having a ratio of two. It is called an octave from the music tradition where an octave spans eight notes of the scale. The second harmonic of a spectral component is one octave above the fundamental. In acoustical measurements, sound pressure level is often measured in octave bands, and the center frequencies of these bands are defined by the ISO. Vibration measurements are seldom expressed as octave band levels, but the US Navy has used 1/3 octave band analysis for vibration measurements on submarines for a long time. Off-line to On-line Running Condition Movement of the shaft center lines associated with (or due to) a change in pressures, temperatures and other forces between the static and operating condition.

Distance between rotational center lines at any given normal plane, usually measured at the coupling midpoint. Usually measured in mils in the US, and mm or microns in the rest of the world. Optical Alignment A secondary alignment method for determining on-line and off-line changes in alignment conditions. This method involves a scale of some type affixed to a machine such that a transit can be used to measure movement of the machine as it grows to its on-line position.

An expression of frequency which relates a frequency (subsynchronous, synchronous or nonsynchronous) to shaft TS. It is calculated using the simple formula: Order=f/TS. In order analysis, the frequency axis of the spectrum is expressed in orders of shaft TS (i.e. peaks may be refered to as 1xTS, 2xTS or .43xTS or 6.77xTS).

Order analysis is simply frequency analysis where the frequency axis of the spectrum is expressed in orders of rpm rather than in Hz or rpm.

Order tracking is a special case of FFT analysis applied to variable-speed rotating machines where the sampling frequency of the analyzer is varied to be an exact multiple of the running speed of the machine while a series of spectra are recorded. The spectra are usually shown on top of one another on the page, and this is sometimes called a waterfall plot. In this way, the running speed and its harmonics will always occur at the same frequencies, or orders, in the spectrum regardless of the machine speed. Other vibration components not related to running speed, such as line frequency effects will not be synchronous with running speed, and will show up as curves on the waterfall plot. A tachometer pulse from the machine is needed to determine the FFT analyzer's sampling frequency. Some analyzers have the order tracking function built in, but others need an external frequency multiplier to derive the sampling frequency from the tachometer signal.

A measure of the total RMS magnitude within a specified frequency range.

In the FFT analyzer, the time signal is stored in a buffer before being processed to form the spectrum. The FFT algorithm only processes the data when the time buffer is full, and after the widowing function, i.e. Hanning, is applied to it. This windowing causes data at the beginning and end of the time records to be represented at the wrong amplitude values, creating errors in the spectral amplitude levels. If two time buffers are used, and if the FFT algorithm is allowed to process the signal alternately from each buffer at a rate faster than the time it takes to fill the buffers, overlap processing is said to be the result. Overlap processing is desirable when using a Hanning Window because it ensures against loss of data for parts of the signal that occur near the beginning and end of the window. Most FFT-type data collectors use 50% overlap processing as a default. An overlap of 66.7% will completely correct for amplitude errors caused by the Hanning window.

The process of evaluating and curve fitting frequency response functions in order to estimate modal parameters.

The maximum positive or negative dynamic excursion from zero (for an AC coupled signal) or from the offset level (for a DC coupled) of any time waveform. Sometimes referred to as "true peak" or "waveform peak".

The amplitude of a cyclic quantity as measured from the rest value to the extreme maximum of the wave height, usually in the positive direction.

The amplitude of a cyclic quantity as measured from the extreme minimum to the extreme maximum of the wave height i.e. The amplitude difference between the most positive and most negative value in the time waveform.

Methods to display the amplitude axis of a spectrum.

A signal that repeats the same pattern over time is called periodic, and the period is defined as the length of time encompassed by one cycle, or repetition. The period of a periodic waveform is the inverse of its fundamental frequency.

A signal is periodic if it repeats the same pattern over time. The spectrum of a periodic signal always contains a series of harmonics.

At right angles (90°) to a given line or plane. Phase (time lag or lead) The difference in time between two events such as the zero crossing of two waveforms, or the time between a reference and the peak of a waveform. The phase is expressed in degrees as the time between two events divided by the period (also a time), times 360 degrees.

The difference in phase angle between the output and input as a function of frequency.

The FFT spectrum is a discrete spectrum, containing information only at the specific frequencies that are decided upon by setting the FFT analyzer analysis parameters. The true spectrum of the signal being analyzed may have peaks at frequencies between the lines of the FFT spectrum, and the peaks in the FFT spectrum will not be at exactly the correct frequencies. This is called Resolution Bias Error, or the Picket Fence Effect. The name arises because looking at an FFT spectrum is something like looking at a mountain range through a picket fence. By a process of interpolation, it is possible to increase the apparent resolution and amplitude accuracy of the FFT spectrum by a factor of ten.

A measure of electrostatic charge and equal to 1×10–12 coulombs.

A class of specialty ceramics tailored to exhibit piezoelectric properties after processing.

A sensor which utilizes piezoelectric materials to produce an electrical signal proportional to the mechanical motion (acceleration).

A piezoelectric accelerometer with onboard signal integration into velocity.

The property exhibited by some materials whereby a mechanical stress causes the material to produce an electric charge. Conversely, an electric field across a piezoelectric material will produce a mechanical strain.

Casing and flange distortion caused by improper pipe flange fit up.

The positive or negative output from an accelerometer corresponding to acceleration corresponding to the force applied.

Electrical requirements, both DC voltage and current requirements, to properly power an accelerometer.

Power spectral density, or PSD, is a method of scaling the amplitude axis of spectra of random rather than deterministic signals. Because a random signal has energy spread out over a frequency band rather than having energy concentrated at specific frequencies, it is not meaningful to speak of its RMS value at any specific frequency. It only makes sense to consider its amplitude within a fixed frequency band, usually 1 Hz. PSD is defined in terms of amplitude squared per Hz, and is thus proportional to the power delivered by the signal in a one-Hz band.

Use of various control systems for operating equipment including machinery, processes in factories, and other applications with minimal or reduced human intervention. Some processes have been completely automated. Automation saves labor, energy and materials to improve quality, accuracy and precision.

A property whereby a change in temperature strains the case of a transducer and produces a corresponding strain signal on the piezoelectric crystal.

Another term for amplification factor.

Another name for the imaginary part of the frequency response function.

A quasi-periodic signal is a deterministic signal whose spectrum is not a harmonic series, but nevertheless exists at discrete frequencies. The vibration signal of a machine that has nonsynchronous components resembles a quasi-periodic signal. In most cases, a quasi-periodic signal actually is a signal containing two or more different periodic components.

Direction perpendicular to the shaft centerline.

The average location, relative to the radial bearing centerline, of the shaft's dynamic motion. Applies only to sleeve bearings.

A plot of the real part of the frequency response function versus frequency. For a single degree of freedom, the magnitude is zero at the damped natural frequency.

In a real mode, all points on the structure reach a maximum or a minimum value at the same time and all pass through equilibrium at the same time.

In the FFT analyzer, the rectangular window is actually no window at all. It is also called rectangular weighting, or uniform weighting, and is used when the signal to be analyzed is a transient rather than a continuous signal. See also Hanning Window.

The consistency (or variation) of readings and results between consecutive sets of measurements. It has nothing to do with accuracy.

Providing the same output signal corresponding to the same measurand input under the same environmental conditions.

Terms added to a curve fit algorithm to take into account the effects of modes outside the range being fitted. These terms consist of a mass term on the low frequency end and a stiffness term on the high.

Lowest level of discernible signal or measurand – Also referred to as “threshold”. i.e. The smallest change or amount a measurement system can detect.

See Picket Fence Effect.

When a forcing frequency is the same as a resonant frequency of the structure, the structure is said to be in resonance.

The frequency response function, also called the response spectrum, is a characteristic of a system that has a measured response resulting from a known applied input. In the case of a mechanical structure, the frequency response is the spectrum of the vibration of the structure divided by the spectrum of the input force to the system. To measure the frequency response of a mechanical system, one must measure the spectra of both the input force to the system and the vibration response, and this is most easily done with a dual-channel FFT analyzer. Frequency response measurements are used extensively in modal analysis of mechanical systems. The frequency response function is actually a three-dimensional quantity, consisting of amplitude vs. phase vs. frequency. Therefore a true plot of it requires three dimensions, and this is difficult to represent on paper. One way to do this is the so-called Bode plot, which consists of two curves, one of amplitude vs. frequency and one of phase vs. frequency. Another way to look at the frequency response function is to resolve the phase portion into two orthogonal components, one in-phase part (called the real part), and one part 90 degrees out of phase (called the "quadrature" or "imaginary" part). Sometimes these two phase parts are plotted against each other, and the result is the so-called Nyquist plot.

Abbreviation for Radio Frequency Interference.

The frequency of maximum amplification for a given damping ratio.

Method for taking shaft alignment readings with indicators mounted radially at opposite ends of a spanned section (on each machine).

See Face-rim Method.

For smaller angles, the ratio obtained when the change in offset between two center lines is divided by the distance along either centerline (between the points of offset measurement) . In effect, it is the slope of one line in a plane compared to another line in the same plane. Angularity is normally specified in mils/inch, or milliradians which is rise/run.

The attenuation of a high-pass or low-pass filter is called roll off. The term is mostly used for high frequency attenuation.

The roots of the characteristic equation are complex and have a real and imaginary part. The real part describes the damping (decay rate) of the system and the imaginary part describes the oscillations or damped natural frequency of the system.

Looseness, usually in a coupling, where a rotor can rotate a given distance before the rotational play is out and the coupled shaft begins to rotate also.

The square root of an arithmetic average of squared values. It relates to energy and vibration damage potential.

A change in dial indicator position at the surface of the rotor during one rotation of the rotor, used to measure out-of-roundness or indicate a bent shaft. See also Eccentricity, Mechanical.

Deflection due to gravity acting on a cantilevered or otherwise supported object. Mechanical brackets that hold alignment tools always sag a certain amount. This sag must be corrected if the machine moves are to calculated correctly.

The act of measuring off-line to on-line machinery movement.

A high sensitivity sensor for measuring low level, low frequency motion of buildings, bridges and other structures.

The output level as measured at 100 Hz at RT.

An accelerometer design which stresses the piezoelectric element in the shear direction: i.e. the electrode faces move parallel to each other. (See Bender Beam Accelerometer, Compression Mode Accelerometer).

A thin piece of material inserted between the machine feet and the baseplate used to produce precise vertical adjustments to the machine centerline. Shims are normally made of stainless steel, mild steel, or plastic. Shims come in various thicknesses from 1 mil to 125 mils.

A system whose position in space can be completely described by one coordinate.

Sidebands are spectral components that are the result of amplitude or frequency modulation. The frequency spacing of the sidebands is equal to the modulating frequency, and this fact is used in diagnosing machine problems by examining sideband families in the vibration spectrum. For instance, a defective gear will exhibit sidebands spaced apart at the gear rpm around the gearmesh frequency.

The maximum amount of short duration mechanical shock that a sensor can be subjected to before the possibility of permanent damage can occur.

A term used to describe any condition where tightening or loosening the bolt(s) of the machine feet distorts the machine frame.

A generic term for any coupling that has 2 flex planes separated by a connecting shaft without bearings or other supports (between the flex points). Sometimes called an insert or spider.

The spectrum is the result of transforming a time domain signal to the frequency domain. It is the decomposition of a time signal into a collection of sine waves. The plural of spectrum is spectra. Spectrum analysis is the procedure of doing the transformation, and it is most commonly done with an FFT analyzer.

An instrument for quantitative spectrum analysis of time varying signals, generally, displayed as amplitude vs. frequency.

Any piece of pipe or shafting that can be removed from a line of piping or shafting without disturbing or disassembling any other components. The name spool piece comes from the physical appearance of the piece, often a short cylinder with flanges the ends, which resembles a spool of string or thread.

If the instantaneous distances from an equilibrium position of a vibrating body are squared and averaged, the result is called the variance of the vibration. The square root of the variance is the standard deviation. It is also equal to the rms (root mean square) value.

A stationary signal is a signal whose average statistical properties over a time interval of interest are constant, and it may be deterministic or not. In general, the vibration signatures of rotating machines are stationary.

Mathematically determining the effect of changing the mass, stiffness, or damping of a structure and determining its new modal parameters. A modal analysis provides, in essence, a mathematical model of the structure. This model can be manipulated to determine the effect of modifications to the structure. The modal model can be generated either experimentally or using a finite element program.

Sub harmonics are synchronous components in a spectrum that are multiples of 1/2, 1/3, or 1/4 of the frequency of the primary fundamental. They are sometimes called "sub-synchronous" components. In the vibration spectrum of a rotating machine, there will normally be a component at the turning speed along with several harmonics of turning speed. If there is sufficient looseness in the machine so that some parts are rattling, the spectrum will usually contain sub harmonics. Harmonics of one-half turning speed are called "one-half order sub harmonics," etc.

Frequencies in a vibration spectrum that are lower than the fundamental frequency.

Synchronous literally means "at the same time," but in spectrum analysis, synchronous components are defined as spectral components that are integral multiples, or harmonics, of a fundamental frequency. They may in some cases exist as multiples of an integral fraction of the fundamental frequency, in which case they are called sub harmonics.

A type of signal averaging where successive records of the time waveform are averaged together. This is also know as time domain averaging. The important criterion is that the start of each time record must be triggered from a repetitive event in the signal, such as 1X rpm. The triggering assures that the phase of the waveform components that are synchronized with the trigger are the same in each record. Then in the averaging process, these in-phase components will add together while the rest of the signal components will gradually average out because of their random relative phases. The technique is excellent for extracting signals from noisy environments.

Movement of the shaft center lines associated with (or due to) a change in machinery temperature between the static and operating conditions.

The percent change in the sensitivity of a sensor as a result of a unit change in the operating temperature of the sensor; express as percent per degree: i.e., %/°F or %/°C.

The temperature span, given by the temperature extremes, over which the sensor will perform without damage. Specifications within the temperature range may vary as a function of temperature.

A measure of the change in a quantity, usually sensitivity, as a function of temperature.

A secondary alignment method used to measure thermal growth. This method is only used for calculating the vertical thermal growth of the shaft centerline due to a change in temperature. The shim plane, under the machine feet, serves as a benchmark. This technique is usually used for machines under 500 HP. The technique uses the linear expansion equation where: Expansion in mils (E) is equal to the average change in temperature, F° (T) multiplied by the vertical distance from the shim plane to the shaft centerline, in inches mutiplied by the coefficient of thermal expansion, in mils/inch F°. E =3D T X L X C This is to be calculated for both sides of the bearing. The number of temperture readings is not critical, but at least 4 is recommended. The average change in temperature is between the offline and online temperatures.

See Discharge Time Constant.

Data taken continuously or periodically and processed as a function of time.

Misnomer for Rotational Play.

Total Indicator Runout. The total movement in mils of a dial indicator after a given rotation of a rotor.

Any device which converts one form of energy into another. An accelerometer converts mechanical acceleration into an electrical signal.

The output to input relationship of a structure. Mathematically it is the Laplace transform of the output divided by the Laplace transform of the input.

A transform is a mathematical operation that converts a function from one domain to another domain with no loss of information. For example, the Fourier transform converts a function of time into a function of frequency.

The Fourier transform of the forced response of a structure measured at one location to the response at another location.

syn. Cross Axis Sensitivity. The unwanted output signal of a motion sensor when subjected to motion perpendicular to the sensitive axis; usually expressed as a percent of the normal axis sensitivity.

A sensor which consists of three mutually perpendicular accelerometers.

Charge generated noise caused by frictional effects within the cable due to separation and motion between the dielectric and shield.

A filter whose cutoff frequencies are adjustable, either manually or under remote electrical control.

In the FFT analyzer, the uniform, or rectangular, window does not modify the signal amplitude at all. It is also called rectangular weighting, or uniform weighting, and is selected when the signal to be analyzed is a transient rather than a continuous signal. See also Hanning Window.

The same as the natural frequency of a structure.

Symbol: v. The measure of the speed at which a mass is moving or vibrating; usually expressed in/sec or mm/sec.

An electrical/mechanical transducer whose output is directly proportional to the velocity of the measured unit. A velocity transducer consists of a magnet suspended on a coil, surrounded by a conductive coil. Movement of the transducer induces movement in the suspended magnet. This movement inside the conductive coil generates an electrical current proportional to the velocity of the movement. A time waveform or a Fourier transform of the current will result in a velocity measurement. The signal can also be integrated to produce a displacement measurement.

Motion in a mechanical system, resulting in various reversals in acceleration relative to a reference.

Interpreting the vibration signature of plant equipment.

The maximum amount of vibration that a sensor can be subjected to before the possibility of permanent damage can occur.

Damping that is proportional to velocity. Viscous damping is used largely for system modeling since it is linear.