VIBRO-LASER instruments corporation designs, develops, manufactures, and distributes resource-saving and energy-efficient precision machine health measurement systems that improve productivity and profitability.

We make reliability a reality through easy-to-use and apply technological solutions for manufacturing organizations worldwide.

Innovation and practical problem solving is core to our DNA. Our talented, and dedicated team of engineers, scientists, and practical application technicians bring the well rounded skills together that deliver the award winning, VIBRO-LASER products customers have grown to count on to solve their machinery alignment and health problems.

We are pleased to present the newest innovation in wireless portable laser shaft alignment technology, the VLSAT. VLSAT is available for Microsoft Windows®, Android® tablets and iOS® for iPad®.

You have a choice with VIBRO-LASER. Select your display tablet option from those we offer, or bring your own device that meets or exceeds our minimum requirements. VLSAT is ergonomically designed for the most rugged environments. This product others an absolutely innovative, step-by-step, responsive interface with 3D-animations and wide touch screen which simplifies the alignment process and reduces the time it takes to complete each alignment.

The unbeatable functionality and the undeniable performance capabilities of VLSAT systems allow you to complete precise alignments for your rotating assets every time. Rugged, Repeatable, and Relentlessly Reliable your VIBRO-LASER VLSAT system will prove to be an invaluable asset in your reliability toolkit.

The VLSAT sensor units use the latest digital, and Bluetooth® data processing technology. Eliminating pre-alignment and minimizing setup time is intrinsically engineered into the VLSAT through the utilization of our exclusive 30mm CCD-detectors.

This provides you with exact and stable measurement results and enables the system to be more interference-immune from the external factors (stray light, vibration, thermal growth etc.).

Thanks to the compact and durable aluminum case of the sensor units, you can work in the most confined and harsh environments.

Azima DLI, a Fluke Reliability company, is the global leader in vibration monitoring, AI-powered analytics software, and expert vibration analyst services. The company was founded as DLI Engineering in 1966 and acquired by Fluke Reliability in 2023.

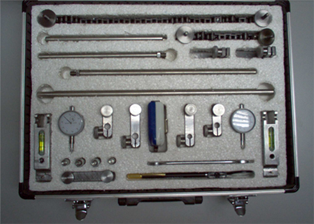

RITEC alignment kit is a powerful tool to adjust shafts alignment using dial indicators accurately and easily. Its flexible components are intended to cater for different shaft dimensions and coupling configurations.

The kit can be used to execute alignment operations for all direct-coupled machine types including:

Pumps, Fans, Compressors, Turbines, Blowers, Reciprocating machines and many other machines.

Kit Contents

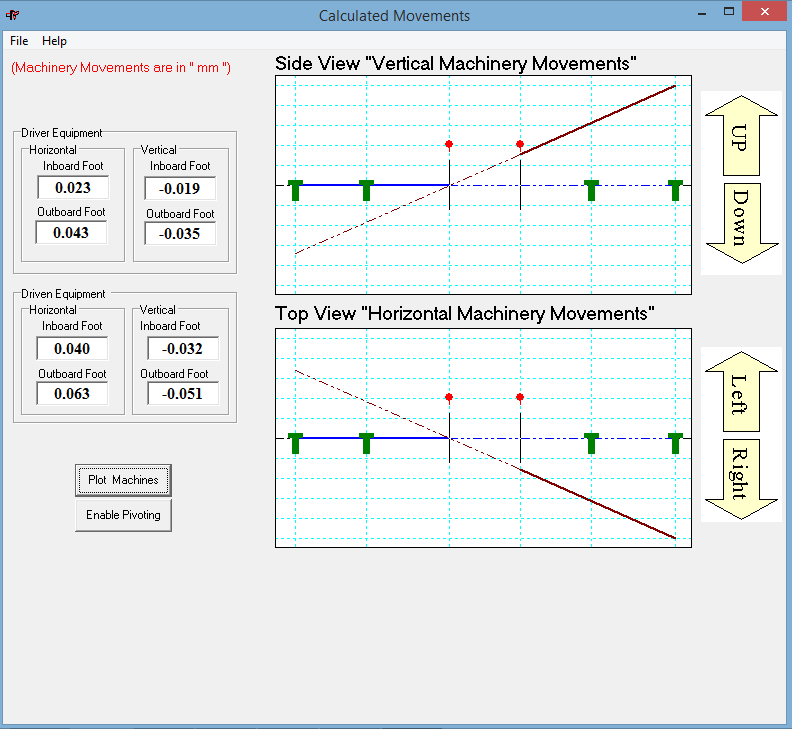

Software Features